Mercedes Sprinter Turbo – Limp Home (LHM) Diagnostics.

You will probably read a great deal on the internet regarding the issues surrounding your Sprinter lapsing into limp-home mode without showing any EML (Engine Management Warning Lamp). I have also read these web entries with interest and have concluded that there is a lot of confusion around what exactly is going on so I have decided to add my own input so that hopefully you can sort out this irritating and troublesome issue.

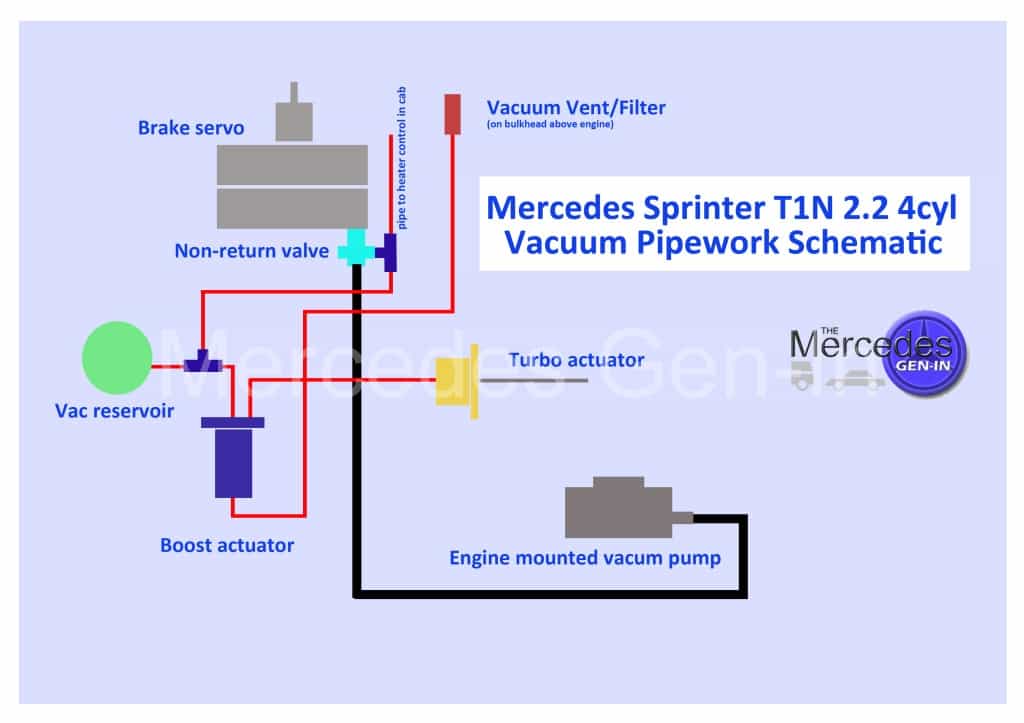

The early Sprinters with vac controlled turbo actuators are quite basic in operation and there are only a few elements to the control loop. These can all be checked out systematically and the faulty element identified and replaced/repaired.

Let me try and explain in basic terms how the turbo control system works so that you may get a better understanding of what is going on:

VNT Turbo and Vacuum Actuator (sometimes known as a VGT Turbo)

Sprinter Vacuum Boost Actuator

The turbo itself is a Garrett VNT variable vane turbo, the details of which you will find elsewhere on this site. ( http://www.mercedes.gen.in/WP35/diesel-mercedes-sprinter-turbo-rebuild/ ) It is controlled by a vacuum actuator that moves a set of mechanical vanes within the turbo to vary the turbo charge rate – there is no conventional dump valve on these turbos and many times you will wrongly read people refer to it as the ‘dump valve actuator’. The charge actuator resides bolted to the turbo body on an extended bracket, its push rod connects to a small lever that enters into the turbo body casting, moving a small lever shaped rather like a dog-bone. This lever engages in an annular ring that in turn interlaces with a set of similar levers attached to each variable vane. A single action of pushing or pulling the actuator rod moves all the vanes inside the turbo in unison, developing more or less turbo charge dependant on its position. Inspect the external lever that the actuator push rod attaches to, ensure this moves smoothly as you accelerate / rev the engine. Look for any misalignment of the lever throughout its stroke as it passes through the turbo body, as the bearing surfaces on this shaft can wear or oval allowing the internal lever to ride over the annular ring inside resultantly not moving any of the vanes. A quick and dirty test to indicate any problems with the variable vanes is to remove the air box or air filter housing and listen as the engine is revved. Once the engine is started, the vac actuator rod should move down slowly as vac builds, this in turn should apply force to the lever moving the vanes into a fully charged position. As you rev the engine you should hear a very loud and strong tornado type howl from the air box, if you do not, and the actuator has moved pulling the lever downward there is a chance that the turbo itself is faulty. Normal operation is as follows. Stationary engine, rod fully extended, vanes in no charge position. Start engine, rod pulls lever downward slowly, vanes full charge position. Rev engine, rod moves in and out during the rev cycle, vanes apply variable charge through rev cycle – Audible howl from air box.

Turbo Actuator Electric Vacuum Control Valve

Sprinter Boost Actuator Valve

If the vacuum actuator is not pulling down once the engine is started check for vac at the pipe, if vac is present, the actuator could be seized or faulty (internal diaphragm split) rectify this. If you follow the vac pipe back from the turbo you will see that it goes to an actuator that is bracket mounted on the inner wing below the air box at the back of the off side headlamp (UK Vehicles) This can be pulled upward off its bracket mounting rubber and moved to a better place for visual inspection. This electrical valve actuator is popularly at fault with the Mercedes Sprinter model and your dealer will have sold hundreds of this item over time. It has a single two wire electrical plug connected to it and three rubber pipes; in some cases its pipe locations are even marked: IN – OUT – VENT. Check vac supply to this device observing and rectifying any split or leaking pipework. Once good vacuum supply has been determined, with the ignition off (no power to the valve and no vacuum present) the route of vacuum should be blocked by the valve to the turbo actuator. The turbo actuator supply pipe should be vented to atmosphere via the electric control valve to a small filter (looks like in-line fuel filter) mounted above the engine and sitting by the side of the brake servo.

Turning on the ignition places a constant 12v to the electrical controlled vac actuator valve, (This voltage pulses during normal engine operation) vac should now be routed from actuator valve inlet to the turbo actuator (outlet) and the vent should now be blocked. Vacuum switching can be verified by using a hand vac pump (Mytivac or similar) Simply sucking on the pipes will not prove anything, as there is an internally sprung pressure control diaphragm inside the electronic valve so that operation will not occur until sufficient vac is present – the only thing you will achieve by sucking with your mouth – is a red face! An old Mercedes engineer once shared that there are two versions of the electric vacuum valve available, one with a blue cap and the other with a black cap, only the matching type should be used as a replacement. I cannot verify this information as I have only ever seen the black cap type, but best practice would suggest replacing the unit only with the correct version to be 100% on the safe side.

Relevant Service Manual Extract View Here

ECU Control

The ECU control loop circuit is quite simple for turbo actuation. The electric vac valve is controlled by simply switching the 12v supply on and off by the ECU, this is called PWM or Pulse Width Modulation – it’s easy to test this control voltage is present with a volt meter at the valve electrical plug/connector with ignition on. If no control voltage is present look for a break in the wiring from the valve to the ECU. Trace back the wires to the ECU connector and prove continuity exists from the ECU connector to the valve. Pin outs and wire colours are given in the included diagrams. There has been commonly reported breaks in the valve supply wiring as it is routed in front of the intercooler behind the grille and also in the area of the near side headlamp where the loom kinks back into the engine bay around the radiator. The wire colours to look for here are white and blue (on my model) but please check the included diagram/chart for correct model notation.

Relevant Service Manual Extract View Here – Wiring Identification at ECU – Turbo Boost

ECU General

Remove the ECU from its slide tray under the passenger dash area beneath the glove box area. It is quite common for the bulkhead grommet to displace where the main ECU loom is routed to the engine bay allowing water to enter and run down onto the ECU connectors. Remove all the connector attachments to the ECU and check for pin corrosion, if this exists clean up both the pin and connectors as best you can. Importantly – reseat the bulkhead grommet.

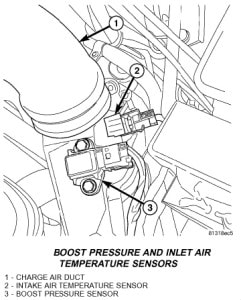

Charge Pressure Sensor / Intake Air Temperature Sensor

Sprinter Boost Pressure Sensor Location

There are two sensors in the control loop, a pressure sensor and an air temperature sensor. They are identified as one having three or sometimes four wires (commonly three) this is the charge pressure sensor. The second is intake air temperature sensor having two wires. They are both located in the upper section of the intercooler discharge hose, on the near side of the vehicle (UK versions) on the hard moulded plastic section of ductwork before the final supply hose to the inlet manifold, just to the side of the radiator. The pressure sensor is attached to the housing with two small bolts. The connections to this device are again simple to understand and test. One of the three wires is ground, the second is 5v+ve supply and the other connection gives an approximate variable voltage output +0.2v to +5v referenced to ground dependant on charge pressure. The other sensor (air temperature) is found slightly lower down the plastic section of pipework, this measures charge intake air temperature. This has a two wire connection that is connected across an internal thermistor bead that feeds back a change in resistance value relative to air temperature inside the inlet pipework, the two connected wires are fed through the bulkhead, directly back to the ECU along with those from the pressure sensor. The temperature sensor should measure between 400 and 500 Kilo-Ohms out of circuit. In the information given it is possible to plot the output from the charge pressure sensor to give an indication of charge pressure in the system, from this you can derive if it functioning correctly or if to suspect it as faulty. If you need to measure what is going on in-circuit without disconnecting these components, take a number of drapery pins and push them through the insulation into the conductor cores of the required wires thus allowing you to connect a test meter and take measurements without the need to disconnect or cut any wires.

Relevant Service Manual Extract View Here – Sprinter Boost Pressure Sensor

You can disconnect any of these components without lighting the EML warning lamp as no indication of a fault is given by the removal of any of these components from circuit. That is why the dreaded turbo limp home fault often occurs without any indication on the dashboard.

Rev Limiter Function

Normally Sprinter engine revs are ECU limited whilst stationary to around 3500 rpm. Depressing the clutch and then further releasing it should now allow revs to increase above this range to the rev limit. If there is a limp home fault, engine revs will not progress above 3000 rpm even when dipping/releasing the clutch when stationary. Once the fault is rectified the rev range and limiter function as described above will return to normal. It is a good idea to check out both of the necessary brake and clutch pedal position switch sensors (on the pedal box above the clutch and brake) and where possible always get hold of a compatible diagnostic code reader as often faults are stored and not indicated with a EML lamp.

I hope this helps you to better understand the function of the turbo boost circuit on early model Mercedes Sprinters and that it assists you to fault find and rectify any problems you may have.

Hi great comments 02 plate 311 cd won’t rev above 3k drives great then a drop in power until you turn it off and on readings are voltage to high on boost pressure and voltage to low on another. Please help thankyou

Hi Stephen,

Worth a check of the wiring to the vac boost control valve, especially round the passenger headlamp. Often this fault is caused by the boost control actuator itself not controlling correctly. Be good to substitute it for another unit if you can beg steal or borrow a spare to conform its at fault before paying out £130 on a new one.

Hope this helps, sorry its taken a while to reply,

Merry Christmas,

All the best Steve

I have a 2004, 316 sprinter with 28k on the clock, I’ve a problem with the limp home mode only when I reach 80 mph approx 2800 revs , I’ve replaced the the boost actuator valve and the turbo works great until I reach 80 mph? I’ve checked the air temp sensor and out of circuit it reads 7k ohms??? Could this be the problem?????

Hi James,

Can you rev over 3000 stationary (quick dip the clutch/then up and rev) if not then suspect first faulty brake pedal switch or clutch switch on the pedal box. Worth looking at the rear lamp clusters as the brake light bulb circuit can give issues if the steel contract track frames have corroded/shorted. Failing the simple solution mentioned you will be best to get the fault codes read with a compatible reader.

Hope this helps

Regards Steve

Hi Steve,

I have a Feb 2006 311CDI with a sprintshift box, I have recently purchased an aftermarket cruise control and fitted as per instructions. With the unit in place I can only select 1,2,3 etc but not “A” The instructions say for a manual connect a wire to the Blue/Green clutch switch for auto leave out (unclear for automated manual). The suppliers of the unit have shut for the xmas break now just wondered if you had any ideas?

The unit is an Autostrada ecruise which is Australian.

Thanks,

Andy.

Seasons Greetings Andy!

The clutch switch will not be connected I suspect unless it is a true ‘manual’ as it disconnects the cruise (as does tapping the brake) Whatever you have connected is somehow preventing the selection of Auto. The signal from the selector to the gearbox ecu is being altered by the connection of the Autostarda. This may be from a disturbed wire or possibly a wrong connection. From what I have read the installation seems quite straight forward as it connects using OEM type connectors in the loom so there is really little to go wrong. In light of this, see if all corrects itself when you remove the unit from circuit. If it does, then double check your work and check again, if its still not selecting Auto do not discount a faulty Autostrada unit – it happens!

Sorry that I cannot be more absolute than that as I have little experience of this unit.

Hope this helps, all the best Steve

Hi Steve,

just to follow up and let you know the outcome, bottom line is I had installed the unit incorrectly, I took the vehicle to Big Brother Security in Perth and Brian very quickly diagnosed the problem which was the brake switch not engaging and a wire connected incorrectly and was able to fix it very quickly. So big thanks to Big Brother Security who I would recommend to anybody with electrical issues in the Perth area and thanks to yourself for a very useful forum.

Cheers,

Andy.

Great news, glad you are sorted.

Regards

Steve

Fantastic. Really helpful. Thank you

Thanks Paul.

Happy Christmas.

Steve

hi steve merry chistmas i have a ml 320 blu tech with a p0234 as soon as i turn on the key noticed the the actuator doesnt go up and down unless i remove the plug on and off i have 12.5v at the connector and a signal 3.5 v on the yellow wire 2008 vehicle thanks for your help im not sur if its the pressure sensor of ther is a calibration to be done after changing the intake manifolds.

Hi Mike,

I would say the charge pressure sensor has been damaged/faulty or its wiring plug or loom section. Its worth looking to check the MAF has been reconnected on the intake (I am unsure if this model has one but think so) Trace back any steps done while replacing the manifolds and double check and check again all connectors and loom.

Let me know how you get on.

Cheers Steve

Hi Steve,

have been reading through your posts and was hoping you could help me. My father has a 2004 413 CDI motorhome he has just bought. it has 2 problems,

1. hard to start when cold, it takes approximately 60seconds to start when cold but will then fire straight away if shutdown and tried again. turns over fine but sounds like a fuel may be bleeding back? can you point me in the right direction before i go looking?

2. i noticed some oil weeping form the intake hose on top of the engine- into the plastic manifold and on further inspection found it is most likely coming from the hose that connects the rocker cover to the turbo intake, is this for blowby recirculation? is it normal to have oil through these hoses? its not doing anything strange and performs ok but don’t want it to become an issue. i have checked the turbo play and it seems fine and doesn’t appear to be coming form the turbo seal.

appreciate the help before i go through everything

Hi Steve,

Thanks for the quick reply! Ill have a look at the non return valve.

The oil around the intake was more of a drip and when I removed the hose I found oil inside(small pool) and oily residue all through the intake hoses.

When I took off the hose that runs from the rocker cover to the turbo inlet hose I could see quite a bit of fumes coming through while running, its either crankcase pressure or EGR ? Do you know what the sensor is for that is connected to that hose? ( small 3/4 inch hose that pushes into the intake hose between filter box and turbo.)

Appreciate the help

Its perfectly normal to have oil traces and some fumes here so don’t worry unduly (unless the fumes are like a fog machine!), its all part of how the engine combusts any blow-by gasses from the cylinders into the crankcase. The sensor you speak of is not actually a sensor its a small heating element that in colder climates prevents this pipe from freezing up and blocking! So no need to worry there. Internally oily turbo pipework normal for these engines unless its excessive, as you can see the crank case oil mist is only lightly filtered then sucked into the intake through the turbo. Thing to be aware of here is if the turbo begins to pass oil from its seals though you will normally see tell-tale white smoke at the exhaust as a first indication that wear here is present.

Have a great New Year

Regards

Steve

Hi Steve,

I have a 2000 model 413, and have the same probs with creep home mode. My problems seem to occur after the vehicle has climbed a pretty long incline, I have just recently worked out that if I turn engine off then restart the problem is solved. It may sound a bit odd also that if I follow the same route (down to our holiday block) the creep mode will occur in nearly the exact same spot, at the top of a long incline ! I used to remove and clean the air temp sender, there is quite a bit of oil in this area, I am pretty sure it is engine blow by as the turbo is dry inside when the air intake hose is removed. I am looking more towards a faulty air temp sender, what are your thoughts ? thanks for your help, regards: Jason

Hi Jason,

Oil in the intake tract is in some respects normal in Sprinter engines, its almost by design. What is concerning however is that the breather pipe is routed forward of the turbo on the inlet pipe, in other words blow by gasses and crankcase fumes are drawn in through the turbo itself and forced into the inlet manifold onward to the cylinders. If you say this is clean and free from any oil deposits then where is the intake oil from? While it would be good to assume sensors I would firstly check all induction turbo hose connections thoroughly from the turbo through the intercooler and to the manifold. Any leaks will be indicated with black oil staining. If its a US model look for cracks in the turbo resonator (if fitted to this model – sorry but my familiarity with US models is poor as I am in the UK) You really need to get a code read from a good independant MB repair shop – this will give you a clue where the fault lies.

Back to my original point of no oil deposits at the intake to the turbo may suggest that the turbo seals are passing oil on the inlet side, indicating the start of possible turbo pressure issues (low charge pressure) Does the engine smoke on the inclines? If you have white smoke oil is getting into the mix (worn engine or turbo), if black smoke then too much diesel and not enough air charge (Worn turbo mechanical parts or engine electrical controls/sensor etc.) If you pull the inlet to the turbo with the engine off and spin the turbo does it spin smoothly? does it catch or snag?, is there a lot of up down play in the spindle? (some play is acceptable) This turbo spools at an amazing 135,000 rpm so you can see how the slightest issue here can cause a significant boost pressure drop causing limp home. Either way you need a code read as a starting point, a fix for this this problem could range from a few dollars to a couple of thousand so you need to be sure… cheap things first though!

Let me know how you get on.

All the best

Steve

Hi there, i have a mercedes sprinter 416 2001, and the heater has stopped working. I dont have a manual. Could anyone tell me where i would find the fuse for the auzillary heating and if it could be anything else?

Wuld be much appreciated.

thanks

Hi Paul, do you mean the fan has stopped running? or the heater control produces no heat when you select hot?

Regards

Steve

Hi All

just a quick note to say I loved the explaination on the working of the system, Secondly It was so good it helped me sort out an issue I have had for about 3 eweeks. The DPF come on and turbo /charger over performance. The DPF I sorted but during this happening it also fouled up the Temperture sensor on the inter cooler outlet. Took me about $1250. dollars after replacing Boost sensor, Turbo control soliniod ans inlet sensor the find out what it was. blew it out with air and prestow, problem solved.

thank you

Hi Raymond, glad you found it to be of some help. Great that you have now sorted the problem and are back on the road.

Regards

Steve

Hi Steve,i have a problem whith my car,Mercedes Sprinter 416 cdi,2004,2,7 cdi, no longer my revs over 3000lps,i change the boost actuator and the vac reservoir,but the same problem,and i can not erase the error (p1407) what else could be?

Hi Denis

That code normally relates to EGR malfunction (P1407). I think this where you need to be looking next as this will cause the issues you have. Chances are its open circuit, jammed open or broken.

Hope this helps.

Steve

sorry,the code is p1470

No probs Denis, usually this relates to an electrical problem (short) with the wiring from the ECU to the Vac valve. Usually breaks chafes in loom touching the body or other conductors as it snakes behind headlamp on the battery side. Can you measure any voltage at the vac valve plug? Is the connector OK or are the pins corroded. The loom travels from the valve across the intercooler behind the grille and sometimes cuts if you have had a mild front end bump at some point. The insulation breaks and the wire corrodes. (Just a suggestion) Trace the wire and check it all out from valve to ECU by the bonnet release in the cab.

All the best

Steve

Hi Steve.

Firstly thank you very much for an excellent article and follow up. You are extremely generous with your time.

My 2004 316cdi has been going into limp mode. Put it on diagnostics and came back with Charge Pressure Control Valve fault. I pulled off the valve and took off bottom cover (end with only one vent that goes to atmosphere) and it looked a bit messy underneath. Bit of corrosion, but not excessive. Couldn’t access the solenoid itself to try and clean it up. Did some tests on the vents and realised that if I blocked the atmosphere vent and left the in and out connections hooked up to vacuum and actuator respectively the actuator worked perfectly well and Van had full power. Only ran it up and down the road as wasn’t sure if this could cause damage. My understanding is that the solenoid when activated blocks the atmosphere vent off anyway to allow the actuator to have vacuum. So obviously the question is can any damage result from doing this until I can afford a new solenoid, as they are around $400 here in Australia and I am halfway into a 1000 odd km round trip.

Thanks again. Any advice most appreciated.

Hi Craig,

The way the valve works is that vac is distributed in pulses from the inlet to the outlet (Turbo actuator) so a rapid series of on’s and off’s signalled electrically from the ECU. The more turbo needed, the longer the on periods in relation to off’s, the reverse applies if less turbo boost is required. The purpose of the ‘vent’port on the valve is to allow the ‘stored’ vac in the actuator to release to atmosphere during an off pulse (Or the actuator position would never change). In short sounds if your valve is faulty, the rust is usually a good indicator of that. Although you have turbo boost now, its most likely not to be working correctly as you can probably see from the above explanation, but apart from using a great deal more fuel and running the risk of further limp home condition lock outs, it should see you home if you have rigged it work of-a-sorts.

All the best

Steve

Hi Steve,I’ve a 2011 sprinter 313 cdi.the eml was coming on an off for a while.if you turn off the ignition it would be ok.but then got worse and worse and it’s on the whole time now flashing.no power in van.not boosting at all won’t go over 3000 revs when driving.losing power going up hills.there was an air noise when you put the pedel down but not now probably cause it’s not boosting.changed egr an mass air flow.any ideas

Hi Brendan.

If you had a whooshing noise when hitting the power, chances are you have a split boost hose or poor connection somewhere in the turbo hose circuit. Have a good look round, look for black oil staining this is a giveaway that there is a pressure leak. Check under the large pipe on the top of the engine this splits underneath where you cant see it.

All the best

Steve

Hi there,

I just want to know where to find the damn engine number on my 2009 myo9 315 cdi van. I just want to check if it is original or stolen. Please give me a detailed description or image would be even better.

Thanks

Hi there,

Should be inlet side above the sump line, or engine mounting point on OM646.

Regards

https://www.maschinensucher.de/bilderuploads/1746661-5.jpg

Steve

Hi Steve

I have a Sprinter 616 CDI box van 2006 reg. I travel long distance I experience my speed goes down without any warning lights coming on! This can happen anytime, if I’m going up a hill the speed will drop to 20 or 30 mph. when this happens I turn off the engine take the key out after 5 minutes when I start the van it works fine. But this is not always the case sometimes it takes longer for the fault to reset. I tried driving the van on 20-30 mph during the fault but my fuel pump leaked. I took the van to two different merc dealers but they have found no problems. They have said to bring the van when the problem happens but as the fault resets its self I am unable to take it down. Please advice me what to do? where should I take my van?

Many thanks

Imran

Hi there Imran,

Do you have a problem with the fuel pump now or did you have this fixed/replaced as fuel delivery could be your problem. Usually its the triangular high pressure pump at the front of the engine that leaks at the joints of each of the three pump heads, once pressure is down the vehicle will behave as you describe.

Let me know if you had this correctly rectified.

All the best

Steve

Hi thanks for your reply! I had a new pressure pump put in by the mercedes main dealer which was £1200 7th August 2014.The van worked just fine. Then 2nd September 2014 same problem I’m on a slop the vans not picking up speed so I went up the slop in first gear with resting it on the way. when I stopped at the near by station someone said its ur fused light which was causing the pick up problem on checking and changing the bulb the van worked just fine! Van worked fine. Now first week of January same problem speed went down I stopped on the hard shoulder I turned off the engine restarted it after 2/3 minutes its fine but no blub was fused this time! I am really fedup this was can let me down anytime. I’v had this problem for 2 years. This van is unique for me its a 7 seater crew cab box van. please help!!

Hi Imran,

That helps a great deal. There is commonly problems with the rear light clusters corroding, sometimes there is a short or very rotten terminals with bad connections. Be sure to look at the connector to plug area this corrosion is hidden until you take off the plug. Also a common area of problem is the brake pedal switch above the brake pedal, even if brake lights are OK on the van there is another set of contacts (more fragile) that go faulty in the switch. Change this first as this will cost about £30 and is an easy change.

Lets assume that all is well with the fuel system and look for simple problems!

All the best

Steve

Hello!

Thank you for taking time to sort all these Sprinter problems! There are little “free” help to get through local MB dealer… “Bring van here and we will check it…”

EGR Valve problem MB Sprinter 318 CDI 2008.

I just want to be sure that its really the EGR that need to be replaced!

The milage is around 140 000km now. When driving the van suddenly drops into “limp home” and will not charge and not rev as usual (tip for you with automatci gearbox: put it in “manual” it will get you going a little bit faster!). If i stop and turn off engine and the restart it, it will run as usual again for a while.

When using our diagnostics tool we get error code 2511 (EGR Valve position, permanent).

We took the EGR-valve out. It looked ok but we cleaned it anyway. We put it back on the van and thought error should be sorted but no. When the “limp home” mode is entered we can clearly hear a change of exhaust nois. Louder than regular. We took the EGR-valve out again and tried to test it with our diagnostics tool that has a test-program for this. The spring valve seems to work as it should but the electric motor gets warm and is not able to move when we run the test program. When ignition is off the electric motor can be moved by hand but as soon as ignition comes on it is stuck…

Some time when working with these parts the engine failed to start at all… when taking the cable to air-mass unit out, it starts… After a test drive all can be as same again (still the EGR-valve possition error).

Does all this point towards an EGR-valve replacement?

Hi there Anders,

From what you describe of the fault and the fact that you have seen the solenoid fault (jamming) occur on the EGR valve when warm it is pretty sure to be that item at fault. It should not be restricted in movement as it is a command open/close device rather like any other on/off valve. I would swap it and see how you go, hopefully it will cure your running problems. Do let me know.

All the best

Steve

All problems pointed towards EGR and YES a new EGR-valve solved this problem.

We bought the EGR from Germany:

http://www.autoteile-online.de €267 + Vat (including shipping to sweden)

318 CDI 2008. Part number from this company is 312123390342. Genuin Wahler part.

Steve, we have 313CDI sprinter which is developing the LHM. Got reading which said over boost 1407 so replaced the boost control valve but really no change. Checked the sensors as per your great article and pressure sensor within the range but temp sensor wiring way out. Motor running 1009, motor off and unplugged 1735

Can I run with the temp sensor disconnected to see if LHM comes back and will this prove that it’s that sensor Thx Trev

Hi Trev,

You will need a plausible temperature signal (This is inlet air temp and not coolant temp correct?) to run without the ECU adding a default value of its own and possibly flagging a LHM situation. It should only be a £20 part to replace the air temperature sensor and probably best swapped out. If it doesn’t cure the problem at least you can eliminate it from your troubleshooting!

Let me know how you get on.

All the best

Steve

Thanks Steve, will replace an advise. One more question, I have read the article on rebuilding the turbo. I have in the past had mine out and tried to clean without dismantling. I sprayed carb clearer in around the vanes and it seemed to improve the flow through the gear changes. Question, if I undo the six bolts on the exhaust side to clean will it upset gaskets, or any other settings. Keen to expose the ring and vanes for good cleaning but not at the expense of a turbo rebuild thanks in advance. Trev from down under (NZ)

Hi Trevor, the gasket faces of the iron casting are just machined, there is a single small dowel that has to be located to maintain its correct position on these mating faces during rebuild. Spray oven cleaner works wonders and someone wrote that barbeque cleaner did a similar good job of cleaning the component parts of carbon build up.

I will say you are brave to attempt disassembly on the vehicle, as there is some fiddly parts and some careful re-alignment to get the vane actuator ring, its rollers and pins, all in place to rebuild. I would be tempted to at least disconnect the vac actuator rod to allow you to rattle the lever in place on the internal ring. Plan a worst case scenario of taking off the exhaust manifold complete to reassemble if you find it does not work out for you. Take off the whole manifold as opposed to the turbo unit itself as you may come across the sheared-bolt syndrome on the triangular flange.

Let me know how you get on.

All the best

Steve

Hi Steve,hope u can help.have a 08 3.5 cdi mercedes van can it has being parked for a few wks and when it was started yesterday engine management light on and was gone in to limp mode,local commercial machanic plugged in in and it came up with particulate filter exhaust differential pressure sensor fault (hope I’m right) he was able to do whatever and it went up to 2000 revs by itself And went it to clearing mode but it was finished within 2 mins and fault was still there,he said it could be 1 of the 2 sensors by the P.F.D,van is go to him in morning to find root of problem. Any help would be great,regards Tom from cork Ireland ps hope u can understand my way of getting it across to u:)

Hi Tom,

It is possible for a dealer to again ‘force’ the DPF cleaning mode with a Star Diagnostics tool if this required. This along with the mechanic’s already pinpointed sensor theory should sort it out. If he is not using a compatible code reader tool there is a chance that it will not be fully drilling down to component level and clearing completely the stored fault in the ECU. That is worth a double check, although I suppose if your man is worth his salt he will have good capable kit. (The reason I say this is that normally you should be able to identify the sensor a little more precisely with a compatible code reader – if using the Snapon Solus it is not too helpful with Mercedes models!)

Let me know how you get on.

All the best

Steve

Hi Steve thanks for your feedback,that was my worry that his hand held kit mightn’t be 100% compatible with my van,he just recently bought this new reader at a cost of €8000,does that say it should be good enough (ill let u decide)he put in the sensor and still didnt fix problem,he said it brought up another fault(that i cant think of right now)but that the 2 vacuum motors are gone,he said it probably was only running on 1 for ages,he can only get his hands on 1 Monday and says it should probably run away on the 1. Would love to know what u think,is it possible that the fault that came up first is all linked to this. I’m worried that all these new parts are being put in the hope that he’ll eventually fix it. I could be doing the man a discredit and ill gladly eat humble pie Monday if fixed,just worried ill paying for things that were fine. Thanks again

Hi Tom,

Not sure what vacuum pumps you are referring to there, I only know the single mechanical engine mounted pump that delivers brake servo vac and supplies a reserve for the turbo actuator and heater flaps circuits. The code reader sounds like the Snap-on Solus with all the modules to make it work with all makes and models. If its by chance an Autel Maxidiag (not anywhere near the price stated) then that one at least should be ok and give a pretty detailed diagnosis.

What I cant fathom is why the vac fault was not flagged on the first read in addition to the DFP pressure transducer? (Is this an aftermarket DPF fitted for LEZ compliance purposes or original OEM? – its on a year change and my 08 does not have the DPF) Its easy to be critical not knowing the full facts and he may be on the right track for you. Lets hope so. You will have to wait on the outcome of the vac pump fitting (whatever that is!)

All the best

Steve

Thanks for the quick response Steve,was only talking to him on phone yesterday so it could be that picked him up wrong,but I’m pretty sure he said 2 motors of vac connected to turbo were gone.as u can say I’m no motor technician

Hi Tom,

I can only think he is on about actuators or control valves, not to worry, see what progress is made and do let me know the outcome.

All the best

Steve

Evening Steve,was only talking to my fella on phone again this evening(as he rang saying he was waiting on second motor to arrive)so as u can see I picked him up right when I said 2 motors off the vac,he said they fun the vac and make it suck in air for the turbo,does this make since to u no

Hi Tom,

The only thing I can possibly relate to here is that maybe it is a twin turbo setup (as its a late model) which may have electrical ‘motorised’ actuators as opposed to vacuum actuators. These motor a rod in and out, moving the turbo adjustment lever to the desired position. These are a modern alternative to a vacuum rod actuator, that mechanically pulls the turbo lever when one side of it is depressed with vacuum (This is not the same depression as you may have when you see the eventual bill on this! Bad joke sorry) The latter uses a control valve and vac supply, the former uses an electrical signal to move the ‘motor’ to a position derived by the ECU directly.

That is the only thing I can think of… That there is a twin turbo set up on some 3.5 sprinters, and possibly yours. This could explain the two ‘motorised’ actuators. Make sense?

I suppose you may know the outcome tomorrow?

All the best

Steve

Evening Steve,u were a 100% on button on what u said yesterday,he put in the second actuator today and guess what >>van is still the same

Hi Tom,

I have a feeling the DPF may be blocked/choked, restricting the exhaust path. Why this would happen after standing for a while I cant say. See if you can force a correct DPF regeneration, if not have the DPF removed and see if runs any better. There are companies that offer a cleaning service for these units but I have read mixed reports as to how effective they have been. Can you get a used one or have yours tested?

Oh just a thought while its been parked up, kids have not pushed something up the exhaust pipe have they…. worth a look.

Bit of reading for you… Its about VW/Audi cars but same stands

http://www.seatcupra.net/forums/archive/index.php/t-263734.html

All the best

Steve

Well Steve I’m finely back to u,fault has being fixed,and low and behold u were bang on the money all along,only my fella ended up putting in a sensor + them 2 electric motor vacuum actuators before he eventually decided to take off exhaust,was all blocked up(so his hand tool like u said obviously wasn’t able to force dpf clearing mode!!!! Still haven’t got bill

That is wonderful news Thomas!

Glad you are up and running again. (it does make the final bill just a slightly sweeter pill to swallow);)

All the best

Steve

Well guys here is my personal experience.Owner of Sprinter w906 315cdi.Limp home and rpm at 3000 with no turbocharging.We take out the EGR valve and wash it very carefully with oil and unstuck the small metal spring that keep it open.I think thats an easy job to do by yourselves.Honestly i don t understand why should pass the exhaust fumes again into the air intake and specially in a such small hole with moving parts.It was a big black and sticky mess and i believe this problem it will appears again in a dozen of klms.I hope this was helpful,keep up with good work.

Hi Steve,

I have a 315 sprinter on a 56 plate,the problem I’m having with it is the limp mode.for what seems like no reason the van went into limp mode with no engine management light showing on the dash, after turning off engine and then starting it again the van ran fine for a few minutes,then the engine warning light started flashing and it went into limp mode again,so I switch it off again and runs ok for a few minutes warning light is then on solid with no flashing and goes into limp mode again.this keeps happening every couple of weeks and then the warning light goes off and van drives fine.this has been an intermittent problem for a few months now,would be really gratefull if you can shed some light on this for me.many thanks craig

Hi Craig,

I will assume that you have the NCV3 Sprinter (newer shape) Apart from the obvious turbo hose leaks there is a common EGR problem. The valve sticks open, you get black smoke from the exhaust and loose power with engine management lamp lit and limp home mode. Without a code read its impossible to tell exactly the problem you have but that would be my first ‘blind’ guess.

All the best

Steve

Thank you for your advise. I have a 1999 312D MWB 4×4 with 150K miles. the van would easily reach 90+mph, a few weeks ago the sprinter went in to limp mode. After 3 mechanics and several hours of searching through forums. The faults lay with a clogged EGR valve and a vacuum leak at what I think is the cabin air intake selector which is located next to the cabin air intake, plugged the pipe with a bolt, vac leak solved. Removed the EGR valve degunked it, valve now in the closed position, refitted it, disconnected the vac pipe to the EGR valve and plugged it with a bolt. (It will never open again!) Cleaned the air intake manifold the best I could with EGR cleaner spray, disconnected the battery over night, later the following day reconnected the battery. The van is now back to normal.

I have decided not to reconnect the EGR valve to the vacuum system as the idea of sucking exhaust gas into the air intake only to be clogged up in few thousand miles strikes me as a little crazy! (I know why the manufactures have to build this system into their engines.)

It seems that vacuum leaks can cause a number of odd problems including low turbo boost, if you have this kind of problem then its worth checking for vacuum leaks.

I hope this will help someone with similar limp mode and low turbo boost problems.

Hi Jay,

Thanks for the input, its a great read. Do you still get any warning in the form of the EDC lamp illuminating? I would have thought the fact that the valve was no longer opening closing and altering the manifold depression as it should would have been flagged and a code stored. Maybe not. Very interesting information for the memory banks – thank you.

All the best

Steve

No warning lights shown, just the gutless performance with limited rpm.

Jay

Hallo guys.

As i described above i had an LHM problem too.If this could help you i would like to say that when the problem appear there wasn’t any engine warning lamp but i understood that there wasn’t any turbo boost.After almost 1500km the engine warning light went on.My opinion by personal experience is that the specific sprinter 315cdi with the bi-turbo engine is very sensitive in the types of oil we using because of residues oil leaves to the engine.I am from Greece and here the best type to use is 5-40 from top quality manufacter.After a little searching i discover that these type of engine has issues when working long tearms in idling.And also don’t forget the dpf filter that makes things more complicated.A re-generation of the dpf is necessary twice a year.

Thanks for the input Bill.

Idle times have long been in the order of maximum of 15-20mins in circles of those in the know. Low ash oils are a prerequisite for modern DPF fitted vehicles. These days regarding the turbo, heat I understand is the primary issue with the oil and turbo. Stop-start driving, especially from highway speeds, without letting the turbo cool down (blow down)for a while before switching off the engine. The resulting turbo heat that is not allowed to dissipate, cooks the stationary oil in the turbo – causing oil based solids to start accumulating in the bearing area and these start to restrict good and proper oil flow.

All the best

Steve

Hi Steve

Not so much a problem as a bit of an annoyance, When climbing one of the rather steep hills here in sunny Wales lol i had the edc and another yellow light flash on fuel symbol with a line underneath it, anyway it’s on the left as i look at the dash once it flashed up i got a total loss of power luckily for me it did it at the top of the hill don’t think i would have got up otherwise as i had a van full of husky’s and gear associated with running them plus half a tank of fuel so had quite a bit of weight on board and was following a friend so had to stay close to know where i was going. As soon as it did it i looked at the dash revs were 3600 when it kicked in. What I am curious about is it supposed to do this? once i stopped the van and restarted it it was fine. I dont’ know if I have a problem developing or not. I checked the fuel filter for water nothing in it other than diesel.

Oh it’s a 311 2003 lwb

Hi Rob,

Done one of these today. When that orange lamp lights with the fuel type icon illuminated, it is indicating often low fuel delivery pressure. This is frequently noticed as you describe, when calling for maximum revs/load – the lamp illuminates and the engine falls into limp mode. (a kind of factory built-in safety mode to prevent engine damage) This will limit rpms to 3500 rpm in most cases. Once the ignition is cycled, this will reset until triggered again.

Usually it is an indicaton of the fuel filter beginning to become less than perfect at passing fuel at high flow rates, and in simple terms requires a new diesel filter installed. If you decide to do this, just make sure you prime/fill the new filter with fresh diesel to the top before cranking or you could have pump priming problems turning a simple job into a more difficult one with a non-firing engine. Prime it until full and you will be good to go.

That is usually the cause, the effect is perfectly normal behaviour for the fault as you describe.

When you replace the fuel filter canister choose the replacement version without the water sensor apertures (sealed canister) as these are less prone to leaking and taking in air. Just tape up the wires in a plastic bag and tuck them beneath the fuel rail.

All the best

Steve

Cheers Steve looks like another job on my list. I have a filter here so shouldn’t take long weather permitting.

No probs Rob,

It really is worth changing to the canister filter type without the water sensor if you get the chance, as it removes a couple of known weaknesses related to the gasketing and poor fitment of the sensor.

All the best

Steve

Hi Steve

I have changed the fuel filter over and van now revs beyond 4200 stationery I did not rev it harder but there was more there. Quick question when I got the filter (which I bought ages ago) I was asked if it was the the one with the sensor on if next time i change it would i have to modify any wiring associated with that sensor if i use the non sensor filter. Also don’t know if it will help paul vinson but i used to start my van with the clutch pedal depressed when it played the no turbo game sometimes it worked. Not always i have since replaced the clutch switch £12.00 of well known auction site.

Hi Rob,

All you need to do is tuck the wires safely out of the way (under the fuel rail) wrap them in a plastic bag and tape them up well. That is all you need to do.

Glad you are all up and running.

All the best

Steve

Hello Steve

I have sprinter 313cdi

when driving on motorway and put in 6th gear

soon it goes in save mode and stops pushing, no turbo boost!

I have tried to clean and spray the actuator arms without luck.

some one told me to change the Turbo!!? its driven 160.000 miles.

Cheers John

Hi John,

Commonly I would associate this to a boost leak of some sort, first port of call would be hoses, connections and pipework – look for black oil staining this is a giveaway of a turbo leak.

Hope this helps for starters..

Regards

Steve

Just got my high pressure fuel pump professionally repaired but now i have replaced it she runs in limp mode. Do i need to put it on a computer to have things reset.

Hi Bryan,

The HP Pump replacement should not usually effect the vehicle running as normal when refitted (codes will exist stored in the ECU but nothing that should hold the vehicle in limp mode unless the fault/another fault remains), however this depends on the original fault diagnosis. Obviously if the problem was the common seal leak on one of the pump heads, that is a good indicator of a fault – but was it for another underlying reason? What was the original problem.

All the best

Steve

Thanks for your reply. The head was leaking when i first started the engine but stopped leaking when it warmed up . Once i put the belt back on (which came of each time) it would be fine as long as it was warm. However it was getting worse each time. I did 100 miles yesterday on limp mode and had to make the same journey this morning and about 10 miles from home everything came back to normal. Could it have been air in the system or something like that. I have to go out again now so I will see what happens.

Many thanks

Hi Bryan,

I pretty much think that an air lock would prevent the van starting and running correctly right from the start, however the pump is a bit of a pig to bleed as it is a complex shape and has many voids for air to hide in. Lets hope it sorts it! There are many causes of limp home mode, only a code read would tell you the true reason – ‘low fuel delivery pressure’ etc. lets see what happens since it seems to have cured itself for the moment.

All the best

Steve

Thanks. It’s still running well figure’s crossed.

Hello Good day, I have a Mercedes Benz C180 and a diagnostic light has come on. I took it by a mechanic and the error on his machine say “error 3539 Boost pressure deviates from the specified value.” Can anyone help me and tell me what this means. thanks a lot in advance.

Hi there Victoria,

I am assuming this is a supercharger petrol car, if so chances are this is a sensor problem in the intake manifold. At the other end of the scale the Supercharger clutches have been known to become faulty and not engage correctly (bearing failure/collapse, not uncommon in SLK200 etc) If the fault is the latter it will be a very large repair bill as component parts are not sold for the supercharger – just the complete assembly. Lets hope it is the former problem that will not cost too much to sort. What you may have to do is entrust the repair to a good independent or take it to a dealer for an in depth code read. This will be using the MB STAR diagnostic tool which should give more direction to where exactly the fault lies and not just a general issue report.

Hope this helps a little.

Best regards

Steve

hi can any one help me my sprinter 313 its telling me voltage is to high on the air pressure switch put new one on and still telling me voltage is to high ware do I go from here

regards mark

Hi Mark,

Usually if the component has been replaced and you still get the P0113-15 code it relates more often than not to a wiring issue. Either a shorted or grounded cable in the run from the sensor to the ECU. I would check very carefully the wiring and make sure it has not chafed or been trapped.

Hope this helps a little,

Regards

Steve

Hi steve

thanks for reply have order new engine loom today i seem to have so many problem with this van at the monment the loom has been cut and tape up due to a fire before i brought the van i will let you no the out come .??????????

regards mark

Hi Mark,

Sounds like you are on the right lines with the loom repair, let me know how you get on.

Regards

Steve

Hi Steve,

Firstly, what an excellent site this is.

I have a MB Sprinter Van 313 CDI first registered 01/10/2010. It had a new engine back in December 2013 out of a ’13’ plate van which had only done 17k. Ever since then I haven’t had the same amount of power, I would guess we are running on aprox 80% power. It also really struggles to tow a trailer, empty or full. Where should I start to look?

Cheers

Andy

Hi Andy,

Was the engine swapped complete or did you swap over your parts? Was the replacement engine from a 313 or was it a 311? Did you check the ECU versions? I think first port of call is to get the van read on a compatible code reader if you have not already done that and see what it shows.

Did you swap over the later newer or clean the DPF? Are you getting repeated regen attempts or lamp illumination as the ailing engine could have blocked this with oily soot if it was on its last legs? Swapping the engine merely connected it to a restricted exhaust and you would of course have a downturn of power.

Give me a little more detail of the swap and I may be able to see any potential for problems.

All the best

Steve

Hi Steve,

Thanks for getting back to me.

When we changed engines (due to cam chain snap), all the ancillaries wee with it except the alternator. And yes it was from a 313.

In the last 16 months since the change, it’s been into garages and Mercedes and had a new DPF. The local garages can’t ever seem to get the correct readings from the ECU.

It’s due to go back in to Mercedes tomorrow as the engine management light is back on again. And I’ve asked them to explore the lack of power. I’m not that mechanically minded but was wondering if it could be something simple like the diesel pump adjusted down as the engine came from a fleet vehicle.

Does this give you any ideas?

All the best

Andy

Andy,

It may be worth mentioning to them when you take it in the lack of performance and that the engine was changed. Let them know (In a round about way) that the injectors are not coded to the ECU (as they are not the injectors that were originally coded to the ECU that is currently fitted) See what they say. Don’t mention any more and see if they offer that the vehicle will not perform correctly (on tune) unless this is done. I have a feeling this may be the source of the trouble.

It is not unusual for independent garages not to be able to read/interpret the codes correctly, more so with late model NCV3 Sprinters. So of that I am not surprised. Although a few standard OBD2 codes can be read and give ‘generic system’ codes, but rarely do the non-factory readers ‘drill down’ to the component level of diagnostics the STAR unit will – so the dealer is really best placed to point you in the direction of the problem. Just be sure to get the fault code print out to take away with you. (Obviously a good independent with a Mercedes STAR can do this for you)

You will need the dealer to ‘code’ the injectors or someone with an advanced alternative reader, like a DRBII. If the dealer does do it however, you may have some leverage with them if it does not improve the situation, especially if you let them say initially that this could be the problem!

All the best, do report back how you get on, I just hope you read this before you take the van in.

Best Regards Steve

Hi steve,

I like to ask you about sprinter 316cdi fault van is 2010 .

As I told you yesterday the van is in limp mode today I described that when I press the break paddle then tourbo start bossting and engine rpm go more then three thousand as normal mode. Kindly reply and share your opinion. Thanks

sameer

Hi Sameer,

What I would be tempted to do as you mention a strange issue related to the brake pedal, is to change the brake light switch that lies above the brake pedal itself, under the dashboard. This is a ‘dual switch’ and has 2 contact sets, one for the brake lamps the other for the ECU signalling. It is the smaller fragile contacts for the ECU that go faulty in the switch body. Least if you change this switch, it will eliminate it as a problem. The switch should cost around £30.

Hope that helps a little

All the best

Steve

Excellent information. Just did all the checks and came right . Pipes were misconnected. Thanks

Can someone please show me a picture of where the coolant temperature sensor is located on a 2008 Freightliner Sprinter 3500 diesel?

Hi Jerry,

If its the 4cyl it will be on the thermostat housing/casting under the fuel filter area, I would assume the same of the 5 cylinder model. I will have a look later if you have no further joy.

Regards

Steve

I have a 2008 Sprinter CRD 3500 diesel. Can you please tell me where the coolant temperature sensor is located. A picture would really help.

Thanks,

Jerry

Hi Jerry,

Based in the UK so assuming you have the same engines as we have here. http://www.moparpartsoverstock.com/showAssembly.aspx?ukey_assembly=1007284&ukey_make=1095&ukey_model=15978&ukey_category=22690 as I have said before it is in the thermostat housing part number 20 the square thing at the back is the connector to it.

here is the image: http://www.mercedes.gen.in/WP35/wp-content/uploads/2015/06/00i83887.jpg

Regards Steve

Message:

Hi Steve,

I am writing from Australia, and love your site. Very

informative. My ’04 W903 313cdi hesitates like it has air in the fuel

system momentarily. I believe i have checked everything except the

throttle pedal. Have you ever experienced issues with these?

Regards,john

Hi John,

I tried to respond to your email a few days back but it was returned undelivered. I decided to post my answer to your enquiry on here in the hope that you get to read it. If you need any further info just drop me an email with your correct contact details on and I will get back to you.

Message:

Is this an automatic model? If so first check the transfer fluid level. Sometimes the gearbox will do this when rolling at about 40 mph and then pressing the throttle, this could indicate an issue with the lock up clutch or valve block.

If it is a manual transmission and the fault is from idle to take off only and drives ok otherwise, depending on what your local version of engine fitment is it could be the manifold air flow meter or MAF as it is called. Substitute this to test.

With the engine running look at the fuel running in the clear plastic pipes just behind the cooling fan area. There should be no bubbles seen, though I doubt this is the issue.

Ideally, as I say to most people, you would be best advised to have the fault codes read by either a dealer or good independent as it should highlight the issues and save a lot of guess work on diagnosis.

Let me know how you get on.

Regards Steve

Steve, I am desperate for some professional help. I have an Australian 906 315cdi 2006 2.1 litre Turbo Automatic Sprinter.I have spent over $3,000 & now have a Van that will not move out of 2nd gear. Originally the problem was a Pause in Motor. When driving at highway speed the power would drop approx. 15km less than whatever I was previously cruising on. (pedal would not accelerate during this time) After 6-8 seconds you could feel a surge & I could accelerate back to cruising speed. The Truck & Bus Mechanics removed & cleaned the fuel tank & filter (said had algae) & when I picked the van up, there was no improvement & had THE ADDITIONAL ISSUE of the broadly called LIMP HOME MODE. At first this would reset at re-starting van. Took it to a large Mercedes Service centre who replaced the oil in the gearbox & said it needed new Torque Converter & Pressure Plate at a cost of $5,860. They also did not test for codes which NOW have many new codes since this 2nd visit to the workshop. I have read so much I don’t know which way to turn. I only hope you can give me some ideas as I did not have this problem originally & also wonder if the 2 issues may be linked. There are no lights on the dash for any of these issues. Thanking you in advance for any help you can give.

Hi Rhonda,

Sorry to hear of your problems. The fact that the van locks into second gear is a result of Limp home. The issue can be caused by problems with the engine or problems more commonly with the gearbox itself. It is my guess there is an engine problem that is signalling the autobox to hold in gear to prevent damage, kind of a safety feature. It is disappointing to read the dealer, with all the correct diagnostic equipment, could not at least ‘clear’ the codes before delivering the van back to you. Your first port of call should be with them. If you have spent a huge sum on the gearbox rebuild/repair and are still having the same issues, then they need to know!

After any major work (engine or gearbox) the engine codes should be reset, some fault codes do not go simply go-away when fixed, unless actually cleared from the vehicle control units (Engine and Gearbox system controllers, ECU etc) and will continue to disable the vehicle until done so.

You need to push the dealer, at the very minimum you need a detailed print out from him of what fault codes remain after he has reset them, this way you will have an accurate direction to your repair, even if you walk away and take your van to another dependant Mercedes dealer this piece of paper will help anyone who is going to undertake the resolution of your problem.

That is what I would do as a lot of cash has so far left your wallet!

You can read a little more on the situation here, Aqua Puttana, Vic, is an internet acquaintance of mine and he knows what he is talking about. The problems of Limp home are explained and outlined here very well and it gives a good background to your investigations.

I hope that helps,

All the best

Steve

Thank you so much for your quick response. I imagine us Sprinter owners keep you very busy. I am going to say that this is not a gearbox problem that warrants the Torque converter & pressure plate replaced. ( I did not go ahead with this repair ) From all I have read (lots & lots) the symptoms of this appear to be shuddering & noisy. My Sprinter gearbox is extremely smooth & silent. I would prefer not to take it back to these two mechanics & being in the country there are not a lot to choose from. I have ordered a Mercedes specific ODBII reader & will do some research on the issue. When I get new clean codes, is it ok to speak to you again about them?

Thank you again.

PS: The ODBII is a MERCEDES BENZ SPRINTER ODB2 CODE READER CAR FAULT SCANNER TOOL iCarsoft i980 from Fuel Economy Solutions America.

Hi Rhonda,

No problem please let me know how you get on. It may even be once the codes are cleared you will be running again as some faults do not automatically reset.

All the best

Steve

Hi Steve,

I hope you can help. I am in the north of the UK and (perhaps foolishly) purchased a 2010 Cdi 313 a few weeks ago from the south. I noticed a few things wrong so before taking it all the way back to where I bought it, I had it checked out a local garage. The main problem is that it Seems to have poor pulling power and has an intermittent engine management light. This is often after a few hours on the motorway (but on one occasion was sooner) and especially up hills on a long journey. Revs then peak at 30000. The local garage confirmed that it was a turbo overboost problem and because there were a few other problems too I returned it to the retailer (under guarantee).

I collected it last week and the problem engine management light etc is still there. (They were vague about what had been done and not being able to speak vehicle, I just had to assume that they had cured the fault!). As it is such a long way to go back again (also very costly in diesel and lack of earnings, cost of hire van for while it is there etc, and also time-consuming) I decided to get the opinion of another local garage in case it could be easily fixed.

This time the garage had ‘Star’ diagnostics under licence and they have said that the fault is “boost pressure deviates from specified value” and suggested damaged manifold pins or faulty turbo and said they would start by checking the manifold and replacing. What do you think please? I have done a lot of googling and have not seen replacement manifold mentioned for this sort of problem. I am trying to establish whether to return the van to where it was purchased yet again or whether to suck the lemon and have it repaired locally. Any advice you can offer would be great.y appreciated. I know nothing about vans but am gradually learning to speak vehicle! Seriously though, this is becoming really frustrating.

Many thanks in advance for your time.

Alison

Hi Alison,

Do you have a print out of the read fault codes from Star?.

Usually that fault is accompanied by another indicating the root cause. For example the ‘boost pressure deviates from specified value’ code is commonly grouped with an EGR (P04000) on this model as this EGR valve component or its pipework often gives problems. If the code is singular and on its own as you suggest, then there is usually a simple cause to a leak of boost pressure. It is associated commonly to a poor sealing of a turbo hose, a small split or crack, even a cracked intercooler tank (not unheard of especially in light frontal damage – not suggesting you van has been in an accident but is a cause) What the garage are saying is along the lines of a boost leak on the intake manifold, and they suspect it on the sealing face of the intake manifold to the engine. This could be the bolts not clamping it sufficiently or indeed gasket failure. I would have expected that pressure escape it this point (or any other of the above listed pressure loss causes) may have been heard as a physical hiss when under load. What you would normally do in circumstances where a leak was suspected and could not be identified, is charge the system with smoke. This is done with a lightly pressurised smoke generating device with the engine not running. This then gives a visual indication to the technician where or even if, there is any induction/turbo leaks. To change parts on an ‘assumption basis’ is not good practice, though often done – even in main dealers!

Any leaks on the turbo hoses or around the manifold joint will normally be identified by being coated in black oily deposits, this is the oil that has been blown out from the intake out to atmosphere. The oil is present in the combustion air by design, as the crank case breathes or vents into the air inlet. This oil mist is usually burnt under normal circumstances, but finds its way out when you have a leak. If there was no oil deposits round the intake manifold joint (where it joins to the engine head/block) and it was perfectly clean and dry, my money would be on it not being there. More likley a hose joint or clamp/seal somewhere. If you take a good torch and have a look around for any oily ‘mess’ around the big turbo hoses this would indicate a cause for concern.

If the issue was due to the turbo, I would have expected other codes related to such a fault, again the ‘boost pressure deviates from specified value’ on its own should not really be too problematic. Remember that the no.1 cause for boost related and limp home problems with the later NCV3 Sprinters is associated with blocked or sticking EGR valves – and I can’t help but wonder if there was a secondary code that would have pointed to this as the main fault but maybe not recorded or passed on.

I hope that helps, it is difficult to make any diagnosis without actually seeing the vehicle, but I think you have at least a few pointers to go on.

My own view is if you like the van, mainly its condition, miles etc then stick with it – these vans are, as you have probably found out, difficult to get a hold of in nice condition. If you engage a good local garage with experience of Sprinters or at least Mercedes Diesels you will I am sure, get this sorted.

Best Regards

Steve

Hi Steve,

Thank you so much for your quick reply. You are an absolute star and have made me feel better equipped to decide what to do next I.e. Whether to take the van back where I bought it or get it repaired locally.

No, I don’t have a print out of the code but the only thing they mentioned after it went on the Star computer was the “boost pressure deviating” code which is also all that is mentioned on my invoice. This coupled with them saying that their next move would be to replace the manifold makes me therefore pretty sure that it was just the one code that was stored but I will ring on Monday morning to double check. I will also ring where we bought it to see if I can find out more about exactly what they did when it went back. I am pretty sure that they mentioned replacing the EGr cooler, (which meant nothing to me at the time) but I can’t remember them mentioned the EGR valve so again I will check.

I am greatly encouraged by your comment that if it was just the one code then it might not be something too problematic and will try to get the hoses checked that you mentioned as it would be stupid to return it again requiring the best part all told of 1,000 miles of diesel and the hire of a van whilst it is there, neither of which is an insignificant expense!

You have already explained more to me than the two garages I have been to so far, and the garage where I bought it. (They have not been unhelpful, it is just the distance issue which is a stumbling block there). Incidentally, since they did a few things the EM light comes on after about half an hour now where it used to be much longer. (It does not go off when you switch off and back on again as some people report unless it stands for about 20 minutes, then it does).

Just out of interest, this might be a naive question but would having this code problem affect overall performance even when the light isn’t showing as the van does not seem to pull anything like as well as the previous ancient Iveco that we had or as well as Crafters that we have had to hire.

I agree that it makes no sense to go on replacing parts ad lib and your comments have really helped. You said it is difficult to make assumptions without actually seeing the vehicle so just out of interest, where are you?

Thanks, thanks and thanks again!

Alison

Hi Alison,

A lot closer than you ever thought possible 🙂

Would you believe Stoke on Trent !

Drop me a direct email to steve@mercedes.gen.in

All the best

Steve

Hi Steve,

I have got a 2010 313cdi the EML has come on and is flashing, i have used a maxiscan code reader on it and 5 codes are showing and are as follows

P2BAC 07E8

PO2A3 07E8

P2463 07E8N

P2BAC 07E8N

P02A3078EN

The van runs but wont rev above 3000rpm and becomes sluggish at 2500rpm. i have also got an intermittent fault on the left brake light. when i brake it sometimes says left brake lamp not working but this doesnt happen every time i brake. i have checked the bulb which appears OK.

Could the two issues be linked

Further to my last, i cleared the codes run the van again and checked the codes and the only one was P2463.

Dave

Hi Dave,

This remaining code is associated to DPF. It may be that it needs a forced re-gen to clear it. This can be done by using the factory MB diagnostics tool and also a few others in the professional line up. Your best bet here is to entrust it to a good independent MB workshop and see if they can re-gen the DPF back to a useable condition. It has been known to be able to flush the DPF with degreaser and a high pressure jet wash if it is still blocked after re-gen. (Have a look on YouTube for cleaning DPF or similar)

Hope this helps

Regards

Steve

Thanks Steve,

Me too – That’s amazing! What are the chances of that? Will send you an email.

Alison

Hi Steve,

AT LAST!!! Somebody on the internet knows what they’re talking about! I own a 2005 Sprinter 616 recovery truck which kept dropping into limp mode and struggled to start when hot. Following your expert diagnostics, I quickly found the turbo lever from the vacuum actuator was siezed solid, and on unsiezing it found the lateral movement in the bearing you mentioned. So, I replaced the turbo and the electric vacuum control valve for good measure. I also found that the O rings on the fuel pressure sensor on the back of the fuel rail fail regularly which result in poor hot starting so replaced these too for peanuts from Mercedes! It now has more grunt than a Siberian pig and starts on the button everytime and has done so for the last three months.

I had to say thank you on such an expert write up by someone clearly very knowledgeable, a rarity for the internet! Being in the motor trade myself, I have no doubt you saved me many hours, and saved a lot in wasted air flow meters and crank sensors etc! I’m very glad I came across your site and I shall keep you book marked! Hats off to you Steve, the beers are on me buddy!

Hi Paul,

Thanks for the kind words. The Mercedes Gen-In site is pretty much a labour of love with its popularity growing at great pace, attracting over 1000 world-wide hits per day quite regularly!. Sometimes though it does feel a little as if it is all ‘take’, and it is especially gratifying when people such as yourself write to show their appreciation for snippets of info they have found useful in the volumes of content added over the past three or more years. Forging ahead in the continuing spirit of the internet where information should be free, its great to get some payback form time to time.

Thanks again, pleased you found the info of use.

All the best

Steve

Hi. Thanks for this post. I wonder if you can help me with issues that i am having with my sprinter 312d. It’s not in limp mode as i can rev over 3000rpm. Although thats when stationary. I haven’t tried to see if it goes over that when driving. Don’t know if that makes a difference. Anyway it’s really lacking power up hill and I’ve read your useful posts and I’ve checked for vacuum. Whilst there is vacuum to the electric control valve it’s quite week. I don’t know how strong this should be. There us no vacuum to the actuator however. And I can’t see where it should be getting vacuum from as the other end of the tube just goes into the turbo casing. Also the actuator arm doesn’t move and i can’t even move it with my hand. I’m thinking this may be seized and I’m about to remove and replace the turbo. But what about the vacuum issue? It’s a auto campervan too by the way.

Thanks for your help.

Hi Matt

First port of call is that actuator, you need to disconnect the arm and see if it is the actuator that is frozen or the turbo itself. (you won’t know this until you uncouple the two from each other) If its the actuator it will be a simpler and less costly fix than a complete turbo.

Hope that helps.

All the best

Steve

Hi Steve. Many thanks for getting back to me on this. To follow up it is all back to how it was. I can only think that it was due to the oil level as I changed the oil outside my house where it is parked on a slight incline. Because of that I put oil in short of the maximum mark to allow for the incline. When out on a test drive (when power loss was noticed) I checked the oil on a level service and it was over the maximum mark. I have drained some out and now it drives very well. I’m wondering if too much oil can activate limp mode?

However, whilst checking out the turbo I noticed that the actuator arm isn’t moving and I had no vacuum to it either. But if I used some needle nose pliers on the lever I could turn it. Shouldn’t this move by hand very easily? I can’t see how a little vacuum could move it otherwise.

Now it seems to be driving as before, could it be that we would notice even better performance if there is a faulty part and I replace it. I know that the turbo itself is fine in so far as the internals spin freely.

Thanks for your help

Matt

Further to my post of June 26th, I am afraid that I will now make everyone on here green with envy! It turned out that Steve is actually based just a few miles from me (what are the chances of that!!!!) and since posting Steve has continued to assist and share his outstanding expertise. Steve, you are a legend!

HI Steve

I still have this intermitent lhm problem this time it happened while i was driving it at a roundabout as I started to cross (not good) also have what i would describe if the engine was a petrol as a misfire slight hesitation on acceleration like a judder but not serious as van pulls through it from 2000 to 2400 ish revs.

What I was thinking was possibly a break in the injector wires as these were coated up badly when it had the black death and I have just purchased replacement plugs and wires and i had to tease them apart before also thought i may have got no 2 and no 3 plug wrong way round colours of wires are front of engine no1 cylinder black with blue stripe and a black wire no 2 black with a purple stripe and a blue wire no 3 black with a red stripe and blue wire no 4 black with a yellow stripe and a black wire I just can’t find anything on which one goes where even my useless haynes shows naff all.

Hi Rob,

I doubt the wiring could be wrong or it would not run at all, the engine would stop if you lost one injector through a bad connection. May be worth looking at adding a tie wrap to hold them in place if uncertain. Check the wiring to the camshaft sensor at the back this is only thin and can get in pretty poor condition if you had to dig it out of the coke! It also runs in a slot in the rocker cover that chafes the outer insulation off. Any loss of synchronisation between cam and crank sensors would cause your issue. However my gut feeling is this sounds more like fuelling or fuel delivery issue. Do you get an engine warning lamp or is it just a hiccup then carry on…

Regards

Steve

Hi Steve