Mercedes Sprinter Turbo – Limp Home (LHM) Diagnostics.

You will probably read a great deal on the internet regarding the issues surrounding your Sprinter lapsing into limp-home mode without showing any EML (Engine Management Warning Lamp). I have also read these web entries with interest and have concluded that there is a lot of confusion around what exactly is going on so I have decided to add my own input so that hopefully you can sort out this irritating and troublesome issue.

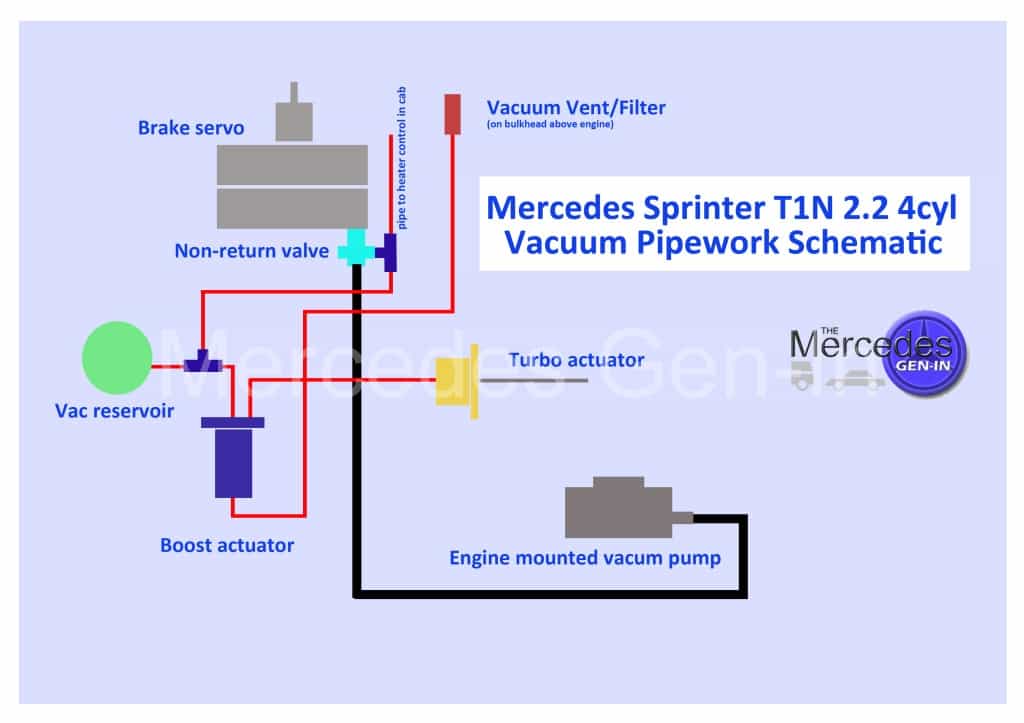

The early Sprinters with vac controlled turbo actuators are quite basic in operation and there are only a few elements to the control loop. These can all be checked out systematically and the faulty element identified and replaced/repaired.

Let me try and explain in basic terms how the turbo control system works so that you may get a better understanding of what is going on:

VNT Turbo and Vacuum Actuator (sometimes known as a VGT Turbo)

Sprinter Vacuum Boost Actuator

The turbo itself is a Garrett VNT variable vane turbo, the details of which you will find elsewhere on this site. ( http://www.mercedes.gen.in/WP35/diesel-mercedes-sprinter-turbo-rebuild/ ) It is controlled by a vacuum actuator that moves a set of mechanical vanes within the turbo to vary the turbo charge rate – there is no conventional dump valve on these turbos and many times you will wrongly read people refer to it as the ‘dump valve actuator’. The charge actuator resides bolted to the turbo body on an extended bracket, its push rod connects to a small lever that enters into the turbo body casting, moving a small lever shaped rather like a dog-bone. This lever engages in an annular ring that in turn interlaces with a set of similar levers attached to each variable vane. A single action of pushing or pulling the actuator rod moves all the vanes inside the turbo in unison, developing more or less turbo charge dependant on its position. Inspect the external lever that the actuator push rod attaches to, ensure this moves smoothly as you accelerate / rev the engine. Look for any misalignment of the lever throughout its stroke as it passes through the turbo body, as the bearing surfaces on this shaft can wear or oval allowing the internal lever to ride over the annular ring inside resultantly not moving any of the vanes. A quick and dirty test to indicate any problems with the variable vanes is to remove the air box or air filter housing and listen as the engine is revved. Once the engine is started, the vac actuator rod should move down slowly as vac builds, this in turn should apply force to the lever moving the vanes into a fully charged position. As you rev the engine you should hear a very loud and strong tornado type howl from the air box, if you do not, and the actuator has moved pulling the lever downward there is a chance that the turbo itself is faulty. Normal operation is as follows. Stationary engine, rod fully extended, vanes in no charge position. Start engine, rod pulls lever downward slowly, vanes full charge position. Rev engine, rod moves in and out during the rev cycle, vanes apply variable charge through rev cycle – Audible howl from air box.

Turbo Actuator Electric Vacuum Control Valve

Sprinter Boost Actuator Valve

If the vacuum actuator is not pulling down once the engine is started check for vac at the pipe, if vac is present, the actuator could be seized or faulty (internal diaphragm split) rectify this. If you follow the vac pipe back from the turbo you will see that it goes to an actuator that is bracket mounted on the inner wing below the air box at the back of the off side headlamp (UK Vehicles) This can be pulled upward off its bracket mounting rubber and moved to a better place for visual inspection. This electrical valve actuator is popularly at fault with the Mercedes Sprinter model and your dealer will have sold hundreds of this item over time. It has a single two wire electrical plug connected to it and three rubber pipes; in some cases its pipe locations are even marked: IN – OUT – VENT. Check vac supply to this device observing and rectifying any split or leaking pipework. Once good vacuum supply has been determined, with the ignition off (no power to the valve and no vacuum present) the route of vacuum should be blocked by the valve to the turbo actuator. The turbo actuator supply pipe should be vented to atmosphere via the electric control valve to a small filter (looks like in-line fuel filter) mounted above the engine and sitting by the side of the brake servo.

Turning on the ignition places a constant 12v to the electrical controlled vac actuator valve, (This voltage pulses during normal engine operation) vac should now be routed from actuator valve inlet to the turbo actuator (outlet) and the vent should now be blocked. Vacuum switching can be verified by using a hand vac pump (Mytivac or similar) Simply sucking on the pipes will not prove anything, as there is an internally sprung pressure control diaphragm inside the electronic valve so that operation will not occur until sufficient vac is present – the only thing you will achieve by sucking with your mouth – is a red face! An old Mercedes engineer once shared that there are two versions of the electric vacuum valve available, one with a blue cap and the other with a black cap, only the matching type should be used as a replacement. I cannot verify this information as I have only ever seen the black cap type, but best practice would suggest replacing the unit only with the correct version to be 100% on the safe side.

Relevant Service Manual Extract View Here

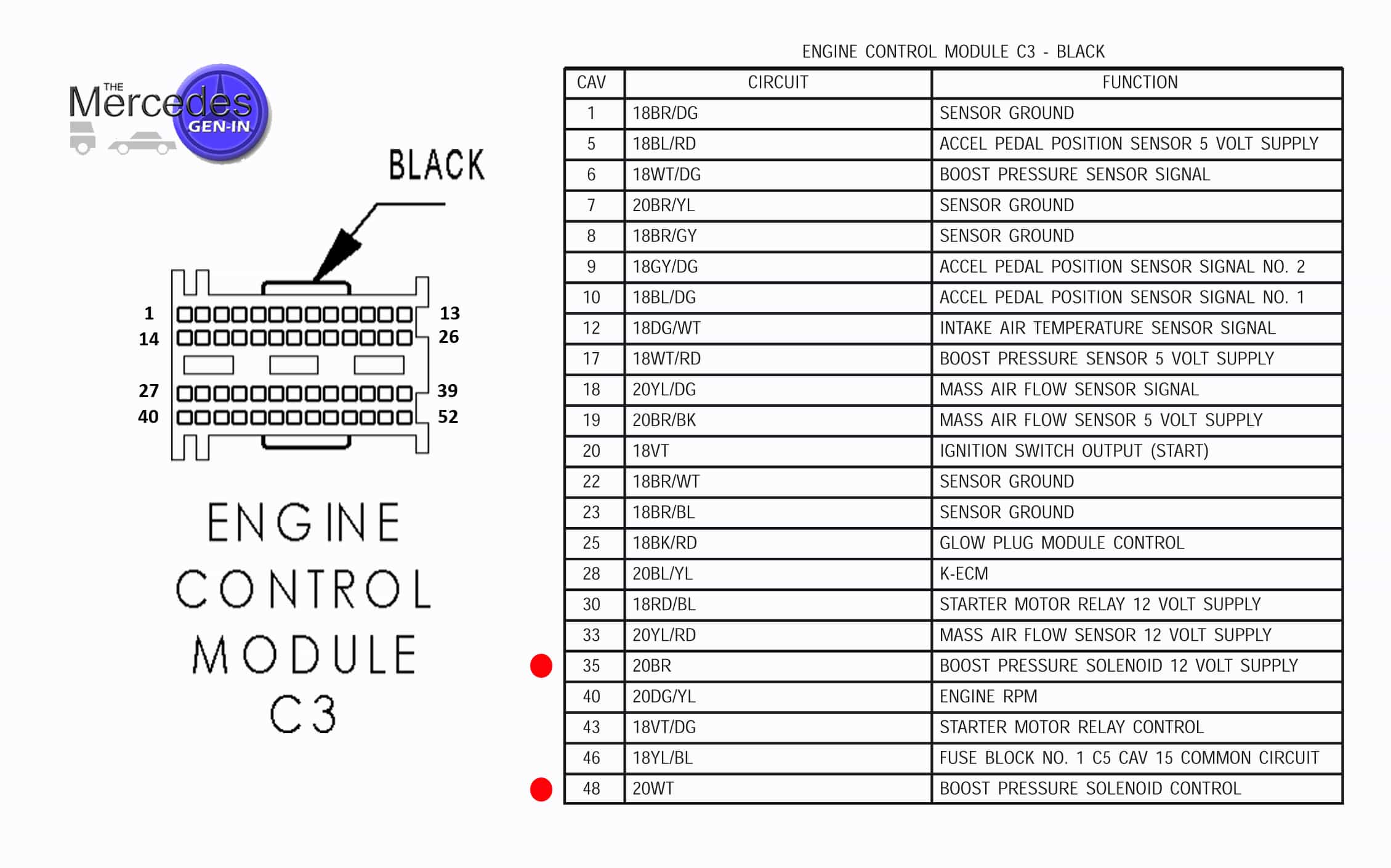

ECU Control

The ECU control loop circuit is quite simple for turbo actuation. The electric vac valve is controlled by simply switching the 12v supply on and off by the ECU, this is called PWM or Pulse Width Modulation – it’s easy to test this control voltage is present with a volt meter at the valve electrical plug/connector with ignition on. If no control voltage is present look for a break in the wiring from the valve to the ECU. Trace back the wires to the ECU connector and prove continuity exists from the ECU connector to the valve. Pin outs and wire colours are given in the included diagrams. There has been commonly reported breaks in the valve supply wiring as it is routed in front of the intercooler behind the grille and also in the area of the near side headlamp where the loom kinks back into the engine bay around the radiator. The wire colours to look for here are white and blue (on my model) but please check the included diagram/chart for correct model notation.

Relevant Service Manual Extract View Here – Wiring Identification at ECU – Turbo Boost

ECU General

Remove the ECU from its slide tray under the passenger dash area beneath the glove box area. It is quite common for the bulkhead grommet to displace where the main ECU loom is routed to the engine bay allowing water to enter and run down onto the ECU connectors. Remove all the connector attachments to the ECU and check for pin corrosion, if this exists clean up both the pin and connectors as best you can. Importantly – reseat the bulkhead grommet.

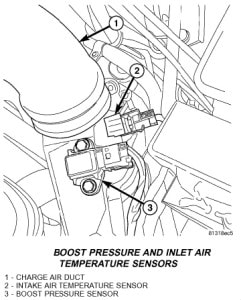

Charge Pressure Sensor / Intake Air Temperature Sensor

Sprinter Boost Pressure Sensor Location

There are two sensors in the control loop, a pressure sensor and an air temperature sensor. They are identified as one having three or sometimes four wires (commonly three) this is the charge pressure sensor. The second is intake air temperature sensor having two wires. They are both located in the upper section of the intercooler discharge hose, on the near side of the vehicle (UK versions) on the hard moulded plastic section of ductwork before the final supply hose to the inlet manifold, just to the side of the radiator. The pressure sensor is attached to the housing with two small bolts. The connections to this device are again simple to understand and test. One of the three wires is ground, the second is 5v+ve supply and the other connection gives an approximate variable voltage output +0.2v to +5v referenced to ground dependant on charge pressure. The other sensor (air temperature) is found slightly lower down the plastic section of pipework, this measures charge intake air temperature. This has a two wire connection that is connected across an internal thermistor bead that feeds back a change in resistance value relative to air temperature inside the inlet pipework, the two connected wires are fed through the bulkhead, directly back to the ECU along with those from the pressure sensor. The temperature sensor should measure between 400 and 500 Kilo-Ohms out of circuit. In the information given it is possible to plot the output from the charge pressure sensor to give an indication of charge pressure in the system, from this you can derive if it functioning correctly or if to suspect it as faulty. If you need to measure what is going on in-circuit without disconnecting these components, take a number of drapery pins and push them through the insulation into the conductor cores of the required wires thus allowing you to connect a test meter and take measurements without the need to disconnect or cut any wires.

Relevant Service Manual Extract View Here – Sprinter Boost Pressure Sensor

You can disconnect any of these components without lighting the EML warning lamp as no indication of a fault is given by the removal of any of these components from circuit. That is why the dreaded turbo limp home fault often occurs without any indication on the dashboard.

Rev Limiter Function

Normally Sprinter engine revs are ECU limited whilst stationary to around 3500 rpm. Depressing the clutch and then further releasing it should now allow revs to increase above this range to the rev limit. If there is a limp home fault, engine revs will not progress above 3000 rpm even when dipping/releasing the clutch when stationary. Once the fault is rectified the rev range and limiter function as described above will return to normal. It is a good idea to check out both of the necessary brake and clutch pedal position switch sensors (on the pedal box above the clutch and brake) and where possible always get hold of a compatible diagnostic code reader as often faults are stored and not indicated with a EML lamp.

I hope this helps you to better understand the function of the turbo boost circuit on early model Mercedes Sprinters and that it assists you to fault find and rectify any problems you may have.

Excellent article. Having problems with my MB Sprinter and I need to know how things work before starting trouble shooting. The engine will not rev and the turbo actuator does not move at all, so the boost valve or the clutch pedal may be where the problem is..

Thanks again.

Paul

Hi Paul,

First off, pull off the vac hose to the turbo actuator with the engine running and see if there is any vac pulling. If not – next measure the voltage at the terminals of the boost valve, if absolutely nothing, check wiring in front of rad/intercooler. If volts exist, suspect boost valve fault. Good luck and do let me know how to get on.

Regards

Steve

Hi again Steve

Success was rather short lived!

Took it for a run and it seemed O.K. to start with but then it was back to normal….poor.

Stopped and lifted the bonnet, The actuator seemed to be stuck. Moved it around a bit with pliers and then whoossh off we went again…like a rocket, the repair guy did say he thought the return spring on the actuator was a bit weak but that was not stopping it going to boost and as we know now, it was the vanes. Someone has suggested grease on the end of the rod/pin to help the action. I’ll use your link above and see if I can get a new actuator and hope that is the final bit to buy. Must admit when it did work it was great to drive and my heart lifted when I realised I could use the motorway again without fearing for my life!

Almost there.

Paul

Hi Paul,

If you undo the two 8mm nuts on the vac actuator (can be done in situ but its a fiddle) and then remove it wholesale. You can work on the shaft as it enters inside the diaphragm housing with WD40. Being able to move it through an extended range and wiggle it often frees off the arm. As long as the diaphragm holds vac all should be recoverable. (Squirt a small spritz inside through the spigot too – shh.. don’t tell the nay-sayers, they will say it will have an effect on the diaphragm material. In truth I don’t know if this achieves anything but I have never known one fail, its always caked in oil and is exposed to pretty extreme temperatures, make up your own mind on that one)

Almost there.. (As one guy said on a Mercedes forum somewhere and it always sticks in my mind – ‘You’re on the pigs back now, you just have to ride it out..’)

All the best

Steve

Hi again Steve,

Well this could be the last lap. Took the van out this morning with the idea of risking it on the motorway. A mile down the road and its in limp mode again.

The actuator lever is stuck again. I wondered if the vac pipe had a blockage in it as water may have got into the vacuum diaphragm as I pressure washed it before I took it apart.

No, the pipe is clear so it can only be the actuator sticking in some way.

So a quick mod, as I’m miles behind with work playing :=)) with this van.

I rummage in the back of the van and I find a short bungee rope with wire hooks on the ends.

So, one end on the turbo lever pin, a small detour round the clutch feed pipe ( to keep the line straight) and then it’s looped around and .clipped to the window wiper mounting bracket.

We now set off and everything works! 50 mile round trip with motorways and some ‘A’ roads with very very steep hills lasting nearly a mile. No problem. I might even say a pleasure to drive. The mod will stay on until I catch up on work and then either a tidier mod or a new actuator.

Well I got on this ‘pig ‘of a van and against what all people say ‘pigs can fly’

My first van with a ‘turbo’ and it started as a real mystery but the mystery has all gone now and although I’m no expert, it all makes sense now and I’ve learned a lot thanks to your website and the people who bring you their problems..

Many thanks Steve.

Hi Paul,

Interesting fix – but I think it pretty much stamps approval on that being the final issue. Lets hope so.

All the best

Regards Steve

Hi again Steve,

Well it’s been a year since I first posted and because I’ve been unable to find your site again and also being so busy, the old sprinter is still ‘chugging away. Motorways are really no go areas as the slightest incline brings me to less than 30mph and HGV’s fly past wondering what I’m doing.

So A roads are my only choice at the moment.

An update. I took your advise Steve and checked the vac to the turbo actuator and there is vac at the pipe from the solenoid pipe. When I connect up to the turbo the lever on the turbo moves down by about 20mm. Engine on tick over.

Driving the van does produce a bit of power from time to time but it is far from ‘a train’ as others claim. I drove a similar sprinter up to Scotland last week and apart from a leaking water pump it went like a rocket.

So I am going to replace the solenoid valve with another, take out and clean the ‘inter cooler’ and check for leaks in the pipework to the inlet manifold.

Now I;m back on your excellent site I will check on others turbo problems and let you know if I make any progress.

Regards Paul

Hi again Steve. Bit late but Happy New Year.

Still struggling on with my Sprinter turbo.

Not sure whether I should have done this but getting desperate now. I connected a large LED light across the wires to the actuator valve (in parallel).

The LED is on all the time but when the turbo kicks in the LED is dim and when the turbo is ‘off’ the light is bright.

I assume that the LED goes dim as the valve drains the power as it triggers the turbo. The turbo really makes the difference when the LED is dim i.e. runs well, but the turbo seems to be random on its working, its on and off state.

Are there any sensors that I should check that are giving this random situation? As the light is on (bright or dim) all the time I guess the wiring to the valve is O.K. ( no breaks).and when the LED is dim the turbo is working and the van is fine.

There seems to be no logic as to when the turbo works, under acceleration or driving almost on cruise the turbo works randomly.

Not giving up yet, but close to it. I’m afraid with my problem and others with similar faults on these pages I think this will be my first and last Sprinter 🙂

Regards and thanks

Paul

Hi Paul,

What you have to remember is people only write more bad than good on anything ! Take a look at the Ford Transit forums with their EGR valve issues and Limp Home, Look at the VW forum and others and you will get the idea.. so everything is the same everywhere! If you want ultimate reliability maybe buy a Toyota Power Van, ironically it is a very little power-van, no performance, no load capacity, in my opinion no style (but who am I to judge). Now I have upset all Toyota owners, lets look at where you are.

If you have a light that is dim when all is well across the coil and the coil is conducting – this then goes bright and the turbo fails to operate – doesn’t this indicate maybe the coil in the valve is intermittent? If the voltage source was disappearing, then the LED would extinguish all together – not go bright. Going bright seems to be an indication of no coil load. Is this a faulty valve I wonder?

Do you see my logic?

Never used an LED like this and not sure what effect it will have on the control circuit, but assuming it doesn’t, then the surely the above applies.

What do you think?

All the best

Steve

Hi Steve

Yes I agree with your comments about Transits and Sprinters, few people go online to say how good their vans are, just the ones, like me, who have problems.

Well I’m trying to see the logic, both you’re and mine. I swapped the valve for one that I was told to be good but still no turbo. The van has been working better today but still intermittent. It does seem to kick in the turbo more when it has warmed up a bit.

I think I’m going to have to get someone to look at it and see what they think. I have a friend who runs a diesel repair garage. If I get somewhere with them I’ll let you know how I get on. Thanks for all your help and if I can get this Sprinter running as it should do I will sing its praises.

Regards

Paul

Furthermore Paul,

let us know each step of the way – so myself others may benefit from the information you come across getting this sorted.

All the best

Steve

Hi again Steve.

Update.

Still having to use the van but dread going anywhere because of it’s lack of power. Had to climb a steep hill coming back from Wigan last week and thought I would never make it up this hill when all of a sudden WOW the power came in and off she went like a rocket!

I guessed that meant that all was well with hoses and actuators it must be the boost valve or the sensors.

So I ordered a new boost valve and fitted it but no luck. As bad as ever.

So I tried the brake switch and messed with it in place, pulling the white pin out and pushing it in with my finger in and out with some WD40 sprayed on it.

4500 revs at stand still. Never done that before. But that was short lived and as I drove away it was no different.

So a new switch has been ordered and when it is fitted I will let you know whether the problem has been solved. Fitting on Monday if it has arrived from the dealers.

If the switch is the answer I will tell you how the LED light works when all is well, it may help others identify where the fault lies.

One other thing Steve, how important to the triggering of the turbo is the clutch switch and can this be over ridden to eliminate that as the source of the fault?

Thanks for all your help. Fingers crossed again.

Hi again Steve.

Forgot to add that as I was messing with the brake switch I noticed someone had placed a cable tie over the brake pedal top lever, where it actuates the brake light switch.

This cable tie I presumed was put in place because the pedal was not pushing the switch pin in far enough to operate something. Turbo or brake light switch, who knows.

I am hoping that this ‘repair’ could be to fix a faulty switch and that a new one may be the answer.

Cheers

Paul

Hi Paul. Sounds like you have found it. The clutch switch has to work as designed too – for example if you take it off, the vehicle will no longer rev over 3200-3500. It needs to be in circuit and needs to be working. Sounds promising so far and a very common problem as the contact set used for ecu feedback are very delicate in comparison the ones used to put the brake lights on – even though they are in the same switch case moulding.

All the best

Steve

Hi Steve

Well the new brake switch is on but still no power. Had to come back on the motorway tonight and could only do 25mph climbing the hill on the slip road to get on. It was frightening to say the least. Can’t go on like this.

The power still seems to be intermittent. I can be driving along with little response from the throttle and then the turbo will kick in and a bit more power is available but it will still not rev above 2000-2300 revs.

I can turn at traffic lights and the turbo works for a second and the van is lively but it does not last and again it will not rev.

That time, a couple of days ago, when the engine revved at over 4000 it seemed like the brake switch would sort it but unfortunately no.

Rapidly loosing faith in the van. New turbo cartridge, new boost valve, new brake switch, and I can understand the logic in the working of them with the ecu but there’s still an intermittent fault somewhere.

What about the clutch switch? Did you say in other posts that this switch limits the revs?

Had a look at the wiring down by the intercooler but it all looks good and the ecu unit and wiring appears dry so, still wondering what it can be. The LED light still shows bright until the turbo works and then it goes dim and the roar from the turbo can be heard and the power is there but no high revs. Thinking of fitting a camera to show the turbo working as the engine is driven, and seeing the movement with speed and power.

Thanks again

Paul

Hi Paul,

Not sure how you feel about this but I think its time to either invest in a compatible code reader or entrust it to someone with access to one! Parts darts gets expensive as you have found. You need to know exactly what the faults are and to be able to access live data and see exactly what is going on. The clutch switch works in conjunction with the brake switch to tell the ECU what is going on. If faulty it will have an effect on the maximum revs and limp home.

Lets stop guessing and start being smart with our diagnostics, you have pretty much done all you can by swap outs, it could even be fuel delivery pressure but you cant see that one!

All the best

Steve

Hi Steve

Latest and hopefully final update.

Long story but it may help others like me struggling to sort out their problems.

I took your advice and eventually took the Sprinter to my mates who run a diesel repair business in the village.

Left it with them but mentioned that I only wanted them to spend a couple of hours on it before it went to the scrap yard.

I had got the new boost valve and foot brake switch from them so they knew they had been replaced. I had also taken the wiring from the front of the radiator and stripped all the covers off so that they could see if that was damaged.

After altering a few earth points on the harness the cables now run over the top of the radiator in flexible conduit so that we can see if there are any problems. The boost valve is now fastened to a bracket over the top of the air filter housing along with the ball reservoir.

Everything is now easy to see and work on :-))

So my mates at the repair shop said it’s ‘the turbo’. No fault codes.

They had checked back pressure in the exhaust system and no faults there, but no turbo pressure. They knew I would investigate further myself so they let me take over and strip down the turbo, again!

Before I did that and on the way home I stopped at another mechanic I know and said ‘drive it and let me know’ After a short drive ‘it’s the turbo’

So I stripped it down. As I checked the vane control ring it seemed to stick in one or two points. Not all the time but every 5 or 6 turns of the ring.

So I stripped down the VG block and there I noticed that some of the vanes had the very slightest damage on their trailing edges, where I presume the old spindle, as it wobbled around, caught the ends of the vanes.

15 minutes later and very careful use of a file and emery cloth and the vanes seem to run more smoothly in the block.

Everything was carefully re-assembled and checked for vane movement and I think ‘hey presto’ it may be working.

So a few morals of this story for me. If I repair a turbo check,check,check for every possible damage deep in the guts of the unit. If I had done that 18 months ago I would have saved a lot of heart ache.

I’m not bothered about the new bits I bought that were not really needed. I’m hoping that the van runs for a few more years without any major problems but if not then I know it’s not the boost valve or foot switch.

So now the final questions Steve.

I’ve taken it for a short run down the country road. Need to put some diesel in it before I go far.

Acceleration is not brilliant until I get to about 10 mph and then I get a surge of power, and then as I gain speed a second surge develops and the van really starts to fly. Is this as it should be?

Secondly I was going to risk going on the motorway to test it out and give it a good run to ‘clear it out’. The back doors are covered in a black smoke film from the exhaust over the last year! Despite constant cleaning.

Should I add anything to the fuel for this run as I have seen in advice for other posts?

Many thanks for your help, advice and time Steve and please keep up the good work.

Singing the vans praises may come in a week or two!

Paul

Hi Paul,

Its up to you but you can adjust the lower point at which useful boost starts, this is done by shortening/lengthening the adjuster on the boost actuator arm. See my post – ‘new turbo, still no boost’. You may decide its not worth it as to have useable boost without tripping over or under boost conditions is a good place to be. If you do decide to tinker then only turn the adjuster on the rod one turn at a time and remember where you are so it can be put back.

A good result all round really, just think what you have learned. It seems on par with most local mechanics!

You can fit a new vane block if you wished. http://www.ebay.co.uk/itm/Turbo-Turbocharger-VNT-Nozzle-Ring-Honda-Accord-Civic-2-2-i-CTDi-/330895490321?pt=LH_DefaultDomain_3&fits=Model%3ASprinter&hash=item4d0ae87d11

I would not bother adding anything to the fuel, spatter on the back doors is normal until the soot is cleared. (its a pig to remove, as you have or will discover washing wont shift it! T-Cut or car polish is about the best at the job)

All the best

Steve

Hi Steve

I may have added my latest update in the wrong place. It’s now at the top of my list, by the first post.

Sorry.

Paul

Hi Steve,

Just wanted to thank you for your excellent article re the LHM on my 2004 Sprinter. After replacing a split charge air hose I still had the loss of power and low revs etc. and spent many hours looking for the fault and was about to take it to my local auto shop and spend hundreds of dollars, before I read your article. It was easy to follow and very logical, I followed all the steps and found the Vacuum Boost Actuator was stuck. I sprayed the turbo linkage end with CRC226 (WD40)etc. a penetrating fluid and after much wiggling the lever became unstuck. Its now back to normal and been ok for quite a few trips.

You have saved me a lot of money, if you come to Brisbane Australia, the drinks are on me. Thank you very much,

Have a nice Christmas and Happy New Year.

Cheers,

Howard Bond

Hi Howard,

Thanks for kind words, I am glad it helped you out with the LHM issue and you managed to fix it yourself!

I may one day even take you up on the offer of that beer !

All the best

Steve

Hi Steve,

I have a 312d based motorhome which is suffering from lack of power issue. We only recentlyacquired it and the service history is patchy. I’am following this thread with much interest and will take a look at the turbo actuator. Is there a a cheapo diagnostic code reader that works with these vehicles ?

Thanks

Paul

Hi Paul,

The best low to mid end solution you can get for your money is the Autel unit. There are a couple of Autel Maxidaiag readers available, the first is for European vehicles only then there is one for all makes. Either will do the job well and also cover transmission and ABS/SRS which is handy! $250 to $300 USD which returns quite quickly if you intend to maintain the vehicle yourself. My opinion – Don’t waste any money on a cheapo $50 unit as they will misread and mislead you as they are not 100 per cent compatible with MB models.

All the best

Steve

Hi Steve,

I’ve written to Autel UK requesting that they recommend a model that is known to work with a Pre 2000 Sprinter. Their reply was that because of my sprinter being old ( 903) chassis only their high end code reader ( £1250 ) would work.

I’ve written to another reputable company in Wales and they said that they are sorry but they cannot help with any suggestions because of the age of the Sprinter.

I’ve been searching all over the internet over the last week to find a autel scanner costing around the £200 – £300 mark but more importantly is likely to work with early sprinter and have met a dead end.

I’d appreciate it very much if you could give me the model number of the Autel scanner.

Thanks

Paul

Hi Paul,

Here is the unit I use, it so far has been compatible with all Sprinters I have used it on. (CDI Turbo Engines) http://www.auteltech.com/Professional%20Scan%20Tools/365.jhtml The covered models in the Sprinter range of the Maxidaiag MD702 are shown on the opening static picture of the video on this page, http://www.mercedes.gen.in/WP35/sprinter-t1n-faulty-injector-electrical-connector-intermittent-limp-home/ this video is taken of the unit I use. If you can satisfy yourself that your model is covered (it should be) then this is the tool for you!

All the best

Steve

Hi Steve,

I purchased the MD702 unit and to read the codes. Unfortunately it was unsuccessful in communicating with the ECU and/or retrieving the codes.

The good thing was I was able to return the unit and get a full refund.

My only option seems to be to take it to Mercedes dealer to get the codes read as none of the independents have the diagnostic reader for a “sprinter of that age” 🙂 .

Thanks for all your advice.

Hi Paul,

That is very interesting, and fortunate that you got a refund. I wonder if the very early models pre-99 were OBD1 and later changed to OBD2 compliance? When you get to the dealer just ask this if you can as it may be possible in the future to get an older OBD1 reader and mate it to the 14 pin connector. – just a thought.

Many thanks for the info and do report back from time to time.

All the best

Steve

Hi Steve,

Since my last comment re diagnostic scanner I’ve discovered that the EGR valve is faulty ( hole in the diaphragm) and soot in that area. Have ordered a new one.

I have also discovered a vaccum pipe going nowhere. Do all 312d Sprinters have Vaccum reservoirs ? Could it be that the vaccum pipe mentioned above was intented to be connected to a reservoir?

Thought I’d check and rectify as many issues as possible before taking it to MB diagnostics to get the codes read ( and hopefully cleared ).

Many Thanks

Paul

Hi Paul,

Sounds like you are getting some where!

From the brake servo vac connection should be a T piece (Actually more like a Y) that is a take off that supplies both the turbo actuator and heater flap/vent controls in the cab. The upper direction of the pipe feeds the cab/under-dash and following the pipe downward should take you to the Turbo actuator under the air box. There should also be a vac reserve sphere here to, often green sometimes black. About the size of a tennis ball with one pipe connection. If you have a floating pipe it could be the vent pipe that goes from the actuator to an area just inside the curve of the bulkhead as it slopes towards the gearbox. (LHS as you are looking into the engine bay UK versions) Usually this terminates in a connection to a small filter unit about the size of a cotton bobbin fastened to the upper bulkhead.

Hopefully this will help you trace where that pipe should be.

All the best

Steve

Hi Steve,

Since my last comment I’ve changed the EGR valve. Also followed ( more like tried to follow) vaccum pipes. There is a pipe that goes from EGR valve to some sort of valve ( could it be some sort of actuator?) . From there there are two pipes disappear into the tangle of wires (possibly to do with heater flap control?). When I start the engine ( with the new egr valve) the egr valve diaphragm pulses for a couple of times and then stays open). This makes me think the vaccum actuator maybe working.

There is small vaccum pipe that goes from the turbo actuator into the inlet part of the turbo. There are no other connections to the actuator. The rod does not appear to move and could be stuck. Could a vaccum pump be used to check this?

As far as I could seethere are no vaccum related items / piping under the airbox. I do not know where they have all disappeared :). A lot of vaccum pipes seem to go into an area under the windscreen. As this is a Hymer motorhome maybe the layout of the piping is different.

I’ve got a well known publisher’s workshop manual but it is pretty thin on details for a novice. It probably would be just the job if I am into rebuilding engines and gearboxes but I am no where near that skill level :(.

Just wondered if you have any suggestions on where/how to get a detailed workshop manual for a 312d.

Thanks for all your help and advice

Paul

Hi Paul,

Have a look here: http://www.boards.ie/vbulletin/showthread.php?t=2056973504 post #20 specifically. It looks as if the actuator could be the place to start now. There is a chance the layout of the Hymer is different than the stock vehicle as it maybe has a different front (body) section. If you pull the pipe off the actuator you should be able to move the actuator with firm finger pressure, if not then investigate further.

Most of the MB manuals other than the Haynes are written from extracts from the manufacturers documentation and as such don’t get any more ‘understandable’ than the one you have. Follow the links menu on the top of this page (far right) and click on the Sprinter Information Resource link – Download the 2003 Sprinter Manuals .zip file. This covers models from year 2000 and should have many common sections and chapters.

If you have no luck with the actuator then take a few digital pictures and email them over of the vac piping and where they go and we will see if we can investigate further. steve@mercedes.gen.in Did I mention about checking the brake light switch above the pedal? Not even sure if it plays a part in the turbo control of the early engine configuration but I am assuming yes. If it is a switch with more than two wires exiting from it, the answer is it probably is included in the control circuit, so for what it costs change it. (V. Common problem indeed, the ecu thinks the brake is on and holds off the turbo) Its a twin switch contact affair and even though the brake lamps are working the secondary contact in the switch could have collapsed.

All the best

Steve

Hi Steve, I have a 2004 sprinter 616cdi ,295,000km and it’s had an issue for many months now which is very frustrating, my friend works for Mercedes as a van and truck tech and cannot solve the issue. So here goes it makes a noise like pinking but it isnt, it had 5 new injectors 7weeks ago it can make the noise from cold but sometimes it doesnt, it’s had a new fuel line the one that comes from the centre of the fuel filter and goes to the lift pump(front top of engine) cos leaking sorted now. It had a new boost transducer 5 weeks ago but didn’t sort the problem the truck goes into limp home under heavy load normally 2000revs ish. It’s had a new boost pressure sensor didn’t sort problem. I’m at my wits end, next is new turbo which I’m ready to do but will be really peeved if it doesn’t sort the issue, also it lack power below 2k and chucks out a lot of black smoke. Hope you can help, also are you based in the uk? Could I come to you as I transport cars and I’m all over the uk

Hi Nick,

That’s quite a rare beast you have there! What you describe are classic EGR valve symptoms, but I am unsure if that model has EGR fitted. I am sure your Tech guy will have the info if he hasn’t checked this already.

I wonder if you have read any codes using Star? I assume there is no EDC lamp on the dash.

In addition to the bits and pieces to check listed in the main post, the noise could be related to a timing issue and if no codes I would swap out the knock sensor at the back of the head/block, (again not sure if this model will have this sensor not sure what year it was introduced) this detects the pre detonation noise and adjusts the CDI injector timing to compensate – could be that. I would possibly have expected a light and a code to be thrown though, but who knows.

It may be worth looking at the intercooler (inside it) and looking to see if its restricted or blocked or as I have found on some high milers half-full of oil, especially if its had had a turbo blow in its lifetime! Its quite an easy task to take this off if you don’t have AC, so wont take you much time to test/look. I would only suspect this if the problem is there all the time and not intermittent.

Black smoke means too much fuel or not enough air – also pointing to an EGR valve issue that when faulty causes smoke, poor performance and pinging noises (if you have one fitted!).

Its worth pulling the ECU from under the dash and removing the connectors, some times the bulkhead grommet allows water in to run down the loom into the connectors causing corrosion/bad connections. Remove the loom plugs and have a look at the pins of the ECU and clean off any corrosion/green that you find.

Your tech should be able to test the boost pressure by measuring the voltage on the boost pressure sensor (pins pushed into the wires) or read the pressure directly from a OBD scanner/STAR reader and so prove that the Turbo is OK and producing boost in the allowable range. Double check the turbo pipework/hoses and look for leaks – especially in the pipes that join the intercooler. Oily mess deposits around hose clips or joints usually indicate boost leaks. Make sure the intercooler hasn’t taken a stone hit and is leaking, again some dark oil staining will usually indicate a problem. Inspect the inlet manifold and its seals/gaskets, especially the plastic blanking plate/end cover at the back (bulkhead end on 4 cyl model, though I think yours is a 5 cyl) that often pushes its O ring out if the van has ever backfired.

Try those few things these don’t entail much cost and if the fault persists rely on your guy with the code reader !

Let me know how you get on.

All the best

Steve

Hi Steve

Had a new turbo today which has sorted the black smoke problem out and low boost pressure, goes like a train, the 616 is the inline 5cyl which doesn’t have an egr, the detonation/pinking noise well I think it is det/pink noise is still there, so questions again…..the knock sensor(Mercs call it a camshaft position sensor) can you tell me more about the symptoms or this playing up and also the air temp sensor. There are no codes,star machine was plugged in today and just had the same codes as before low boost pressure which is now sorted and glow plugs of which two are not working and the tech disconnected the plug a little while ago as the two had gone down but they wouldn’t come out of the head and the tech didn’t want to risk them breaking off in the head so disconnected the plug,apparently in the uk the temp doesn’t go low enough for them to come into play.

Hi Nick,

Thanks for the update. Glad the smoke/power issue has gone – at least some compensation for the expenditure on the new turbo, well worth It!

Before trying anything else, run your tank as low as you dare, fill half up with BP Ultimate Diesel and then add a Cetane booster (Like an octane booster for petrol but for diesel) This one is a good one. Don’t bother with the Redex branded booster as it only specs a Max Cetane boost of 2, the Millers specs a 5. Let it run for a few miles and see if that cures the pinking noise. Some diesels seem to favour better performance diesel fuel than the ‘Supermarket Stuff’ If its no different then begin to look at the components that control the injection timing. You have new/recon injectors so they are out. Cam sensor and Crank Position Sensor are the only other links in the chain. Almost every van I have seen over 10 years old has no working glow plugs! They all start and run fine – ask any courier company with the older model sprinters. So discount this and not worth the risk of replacing/fixing. The intake air temperature sensor is in the intake tract and would flag a code if faulty. I bet you are running your 616 on low quality diesel. (just a guess – don’t shoot me down!) Try the Cetane booster and monitor the effect. You are getting there !!

All the best

Steve

Hi Steve again……

I run the sprinter on shell diesel only and once a week run it on the nitro diesel, I’ve used millers octane booster before and can’t say it has made a difference, the noise it makes is difficult to describe and mainly does it on what I would term neutral throttle, In between acceleration and not. It’s so frustrating, it’s driving my (friend) Merc tech mad

Hi Steve,

Just for your knowledge and folk on here the noise which had been there for sometime gradually got worse on Thursday morning and she finally let go(no.5 piston ). I’m a little disappointed with only 300k on the clock but when I bought the truck it had 120k on it and who knows the history of that mileage and 9years. Anyhow what are the best tips for running in the new 5cyl lump which is new from Mercs?

Oh dear!

That is sad news. So what I guess you were hearing as ‘pinking’ was in fact the little-end of No.5 beginning to oval. That’s how it is some times sadly, we would all do with X-ray eyes!

With regard to running in, just use common sense, don’t labour or over-rev it. The extract from the Mercedes Handbook shows the following:

…………………………………..

Running-in

It is of decisive importance for the operating life, reliability and economy of the vehicle that the engine is not subjected to its full rated load during the running-in period.

Up to 1,500 km

Run the vehicle in carefully. Drive at varying road and engine speeds.

Avoid heavy loads (driving at full throttle) and high engine speeds. Do not exceed 3/ 4 of the maximum speed available for each gear.

Change gear in good time.

Do not change down a gear manually in order to brake.

Avoid depressing the accelerator pedal beyond the pressure point on vehicles with an automatic transmission (kickdown) and only engage gear 4, 3, 2 or 1 while driving slowly.

After 1,500 km

Gradually bring the vehicle up to full road and engine speeds.

These instructions must also be observed if you have the engine, the transmission or the rear axle differential of your vehicle replaced.

……………………………………………..

Good luck with it Nick its a shame it ended this way but at least you will know its history from here forward! Drop the oil and change the filter after 3k if you want to really do the job right as it will rid it of all the running-in debris.

All the best

Steve

Hi Steve.

I also have the Sprinter 616cdi here in New Zealand. This one had the problem of cutting out altogether at random times while driving. I don’t believe I have done anything to fix this issue however from the beginning of winter, or the colder days this problem has vanished 100 percent. Its as if the air intake temperature had something to do with it…..Anyway, I was looking forward to how it would react in the summer months but I now have a bigger problem. I stalled truck in 1st gear, it took about 20 sec to restart then was sluggish. Then just as I was realising this it gave the death rattle! Could it have jumped a tooth on timing chain? Am I hearing valves hitting pistons? We are about to pull engine out and start stripping. Will look for damages then asses what to do from there but am thinking another engine. Is there a good workshop manual around which will guide me regards engine work? Thanks. Dan.

Hi Dan,

Good luck with the rebuild, the best resource for Manuals and info will be here Sounds like cam chain issues as you report. Be interesting to hear what is the result of your investigations. I hope the links to the info covers all you need – if not with a little thought most of the info can be applied to your model as a great deal of the ancillaries and parts configurations are common between models.

All the best

Steve

Hi I have a Mercedes 413 cdi diesel turbo sprinter leisure seeker winniebago in the last few months we have been having trouble maintaining any speed up hills seems like we lose power all though on the flat it seems ok most of the time any suggestions please

Hi there,

My suggestion would be to check all hose connections on the induction side, post turbo. It sounds if you may have a boost leak under heavy load. Check all the hose clips to and from the intercooler, if you see oil staining/film around the joint there is a good chance you have found the source of the leak. Check also the large induction hose that goes to the inlet manifold, this splits underneath, along its length where it escapes casual inspection by eye. Take the hose off and look for faults by flexing the hose between your fingers. I will place my money on this being the problem. Good luck.

Regards

Steve

Hi steve can you help!

I have a 56 plate sprinter 311 I was driving it home on Saturday I pulled over and turned it off. I then started it up and pulled off I started to get to about 85 and then it started to slow down and I found not get anymore than 65/70 and Struggled in sixth gear,and now it feels like the abs is kicking in!? Can you help please

Hi Duncan,

It would be good to check induction hoses for leaks, especially at the joins/hose clips to the intercooler. Usually oil staining indicates a boost leak at the joints. Make sure the vac hose to the turbo actuator is not split and is a good fit on the spigot. Check out the other fault finding tips in the post and let me know how you get on.

All the best

Steve

Thanks steve

I’ve only just got to read this. I’ve been into my local garage today they plug it in and it worked fine for about 30 miles. I’ve gone back to the garage again this evening they plug it in and they give me a fault code of 2511 which I don’t know what it is,so they cleared the fault again but now it’s gone back into Limp mode again and now the engine management light has come on with the esp light, can you help me on this one thank you

Also the EGR code come up this morning

Hi Duncan,

I would guess there lies your problem: Code 2511 (001) Component Y27 (Exhaust gas recirculation positioner) does not function properly. Positioner signal fault.

Here is your first port of call. It may be you can get away with cleaning it but I am unsure if there was a recall 06,07,08 with this component as it was modified because of reported failures (This may have been on the Vito but remains sketchy in my memory) Either way this is the best place to start. Its a rotary device driven by a stepper motor and gets all gummed up with soot. Worth a try.

All the best

Steve

Hi Steve, can you help please?

I have a 2005 311cdi which has an intermittent LHM fault and similar to Duncan’s it feels as if the brakes are on.. It can be fine for a 1000 miles or do it 3 times in less than 5. Sometimes the turbo kicks back in by itself after as little as 5 secs, other times it needs the ignition switching off and restarting.

I found that the jubillee clip on the charge air pipe was a bit loose where it connects to the sensor housing (very oily) which didn’t cure the problem. Since then I have changed the both the boost valve and sensor but still no permanent fix.

As a european courier it doesn’t take long to do a 1000 miles. thing I have noticed is that when in LHM if I press the clutch in the engine revs let the clutch back up and its stuck at 3000.

Any advice that you could give would be very much appreciated,

regards

Mike

Hi Mike,

If you have checked most of things mentioned in the blog post then it may be a fuel pressure or fuel pressure sensor problem. There is a pressure transducer that lives in the end of the HP fuel delivery rail and it is quite common for the two ‘O’ ring seals to perish and cause some issues, although usually its more to do with starting than low boost. However the most sensible thing to do would be to get an independant garage to read the vehicle and list you the fault codes – go straight in and sort the defined issues instead of the ‘scatter gun’ approach that often runs away with money at a great rate of knots.

There is one other thing that I have had cause similar problems – on the right hand side of the engine under the bonnet, beneath the inlet manifold you will see the low pressure fuel delivery sensor in a T piece connector. This has a connector that faces down toward the road and often becomes loose or a poor connection, should this electrical connector become disconnected or corroded, the ECU gets a ‘high fuel delivery pressure’ signal and cuts back the vehicle into LHM. I cannot say that this will be the cause but on more than one occasion now this has been the problem and is well worth the short time to check before moving on.

You may wish to have a look at a fellow posters information here: http://sprinter-source.com/forum/showthread.php?t=7173 there is a few pointers and suggestions for you to try without me retyping. I really think the best advice would be to get the fault codes read and move forward from there.

I hope you get sorted, do let me know what you find.

All the best

Steve

Hi Steve, many thanks for your reply, I’ve been a reader of the posts on sprinter source as well as other similar forums and found them very useful in the past. Your write up on the subject I found to be the most informative.

I understand what you mean about the scatter gun but seems to be the approached used by both Mercedes and the local garage. My faith in the so called professionals is somewhat lacking because despite their “Diagnostics” into the the fuel problems which kept tripping the EDC system as well as poor running its had a new fuel pressure regulator, hp pump, fuel filters, all 4 injectors reconditioned (they were over fueling but it didn’t cure the fault at the time) hours of pondering and avoiding phone calls. It was finally fixed on 1 occasion by me replacing the return valve on top of the fuel filter (thanks sprinter source) the other 2 by the garage repairing a damaged wire in the engine loom. Over £2000 spent and fixed with a bit of black plastic and some wire.

This intermittent LHM started occurring before the above so feel that it not fuel related. The ecu has logged the following codes amongst others over the last 3 visits.

P1470 Charge pressure low

P1470 Charge pressure neg Control, Charge pressure low

P1470 Charge pressure neg control, charge pressure high

P0105 B5/1 Charge pressure volts to high

This what led me to changing the parts that i have,

I will check out the sensor you suggest as that is 1 thing that hasn’t been replaced.

Could you tell me the purpose of the clutch switch as detailed in your write up when the van is moving? it will rev freely with clutch pressed in when in LHM mode which you say won’t happen with the van stationary.

The other thing i hope you could tell me is what is the sensor or component that is in the crank case vent hose where it joints the turbo air inlet? the wiring for this also runs through the main loom where there has been so much trouble.

Thanks again for your time in replying to my post.

regards

Mike

Hi Mike,

It does seem that the boost pressure is up and down, or at least the reported signal to the ECU is, that P1470 indicates that. Give the pressure sensor a try, I have indicated the position of this on the T1N Sprinter in the write up somewhere and am pretty sure you will find it in a similar location. I think often even the ‘so called experts’ are baffled by what they see on the code reader, the truth is they are and have been trained to use that alone, all the old fashioned fault finding – understanding the principals of what is happening – now plays little part in modern diagnostics. Indeed often a problem with one element will cause an indication on the code reader that is more of a result of the problem than the cause! I have always found it better to try and understand the issues along side what the ‘magic device’ tells you, this way you get a better focus on the problems at hand. (My two pence worth anyway)

There are two switches at play on the pedal box, the first is the clutch switch that stops the vehicle being over revved when stationary, this can be over ridden by the ‘up down method’ to test and see if the engine will rev over 3000, in other words see if it is in a fault condition without showing an EDC light etc. The other is an area that may be worth a look is the brake light switch. This is a dual switch and lies not surprisingly above the brake pedal. This not only provides the signal to the rear stop lamps but there is a second set of contacts that tell the ECU that the vehicle is being retarded and signals not to apply boost. You can test this out on a vehicle that is working correctly, drive in 3rd gear at a medium pace, then cover the brake with your LEFT foot and while applying gentle pressure to the pedal, try and accelerate with your right foot on the throttle – it will not allow you to and the engine stumbles! I suppose this is a ‘fail safe’ that if in an emergency braking condition you stamp the boards, catching the throttle with your size 12s would not make any difference to the level of stopping distance. I am pretty sure that it is just a safety feature. The dual switch body is a known trouble spot, just because the brake lights work, does not indicate that the secondary part of the switch is functioning correctly. Could be worth a look – its known but rare that this gives problems – but who knows!

The ‘T Piece’ device with a pair of wires to it you can see in the crank case breather hose, where it joins the turbo inlet pipe (from the air box) is in fact a small heater ! This operates in extreme low temperatures to stop water vapour or emulsion from freezing in the pipe blocking the crank case breather so I doubt that this will be the source of the problem even though its supply is in the suspect loom section, unless of course it is shorting out and causing fuses to blow etc.

I hope that helps you out Mike, keep in touch and let me know how you get on. I am about to go and change a disc and pad set on a LWB 313 this morning and then onward to a front spring and leg on a Clio, so a busy day ahead – hope the weather stays good.

All the best

Steve

Hi,I have a sprinter motorhome based on a sprinter 416, 2001.Heres the problem,took the van for a mot last year,passed no problem,but seemed to be very under powered on the way back home ,30 mph roads,thought nothing of it.Went away on holiday to holland,very flat roads,seemed under powered on the way there.but coming back home up the A14 ,read long hills there was no power at all.The van seemed okay before the mot, the only thing that I can think of is when the engineer asked me to rev the engine for the exhaust gases to be analised I reved it alittle harder than I would normally do.It was only for asecond or two.Would this cause the engine to effectivly go into limp mode,nothing showing on the dash;Many thanks.

Hi Russ,

The MOT blast should not really have caused any issues, its more likely if it is connected to this event that a Turbo boost hose is leaking or is split allowing boost to escape. On this age of vehicle not always does an EDC lamp illuminate. Check all the hoses and connections post turbo, as I have stated before look for black oil staining as this is usually a dead give away to the location of a boost leak (especially on the intercooler entrance and exit pipes). Check the vac connections are sound and that the turbo actuator moves on a rev. (No movement = no boost being called for) The manifold/boost pressure sensor may be faulty / misreading, its a cheap component in the big scheme of things and is well worth a swap. Really all the fault codes will be stored, if you can get them read and then just rectify ‘exactly’ what is indicated as the problem and see how you go. Often £40 spent at an independent for a code read at this stage will save you a great deal of time and money in the long run.

Good luck, do let me know how you get on.

All the best

Steve

Hi,steve ,just need to add that my sprinter has the sprint shift gear box,thanks for the easy to follow logical approach to the problems listed.Russ

Hi steve ,thanks for the reply have been busy with work lately but we plan to go away in a week or two so I thought I had better look at the van again.took It up the motorway today but there does not seem to be any boost from the turbo.At home I have taken the air box off to check for any thing obvious.There is a tiny air leak from somewhere,but the van has always had this slight leaking sound after turning the engine off, it lasts about 1 min then stops.I have traced it to the turbo boost actuator valve.Heres the brain stormer……if I disconnect the tube from the turbo boost actuator to the vacuum actuator,and place my finger on the connection under the turbo boost actuator ,where I had pulled the tube from, the air leak stops and I feel a suction on my finger.If I start the van with the pipe still off the vacuum actuator not alot seems to happen but If I keep the pipe off and then put my finger back on the bottom of the turbo actuator the air intake sounds like a turnado, if I pull my finger off again the rushing sound goes again.So is the boost actuator at fault or is the vacuum actuator leaking air to the turbo actuator?The connection pipe between the two seems okay.Many thanks.Russ

Hi steve, I have got my information mixed up!I have double checked today…..the air leaking sound is coming from the boost actuator.Its coming from the ventoutlet for about 1 min after the engine is turned off,the noise stops when I put my finger over the vent tube.When the engine is stopped,there is suction on this pipe ,WHEN THE ENGINE IS RUNNING THERE IS ALSO SUCTION ON THIS PIPE!.If I start the engine with all pipes connected except the vent pipe(under the boost actuator), the vacuum actuator pulls the turbo rod down hill as it should,if I rev the engine the rod does move slightly up and down,but the vent tube connection under the actuator is sucking in air ,quite strongly,I thought that once the engine is running there should be no pressure on the atmos- vent?Whilst the engine is running I got my son to rev it alittle whilst I messed about under the bonnet,what I found is that if I block the atmos-vent with my finger and revved the engine the vacuum boost arm woiuld not move but the air flow sounded like a tornado,does this mean that the boost actuator is stuck and not changing the pressure in the actuator from atmos-vent to boost valve? I have taken the boost valve off the van and pushed its rod back into its body(as if it were in vacuum state) then put my finger on the inlet tube under the unit,the rod moved back only alittle and stopped in position ,keeping avacuum until I moved my finger off the inlet tube,so I guess that its okay.Many thanks ,Russ

Hi Russ,

If you have removed the air box you will see a small plastic ball about the size of a cricket ball. This is the vacuum reserve – make sure this is not the source of the leak, if so replace – this is providing the vac you can hear once the engine is off. From what you explain it seems more likely the actuator valve is faulty under the air box and not functioning as it should, especially as you say it makes a loud sucking sound. The ‘atmos’ is a discharge vent (breathe out) that vents stored vacuum in the turbo actuator line via the valve allowing it to extend the rod again when needed. Constant vac here would most probably indicate a leak internal to the valve – at least something is not as it should be with the actuator valve!

All the best

Steve

Thanks Steve,I have ordered a new boost actuator,or as my merc dealer calls it, a transducer…should be able to fit it early next week,will let you know how things progress,heres to fingers crossed ! P.S I have also ordered a pressure sensor so will fit this at the same time.Many thanks Russ

Hi Steve,just a quick up date on the van,I replaced the boost sensor,actuator valve and the vacuum reserve( still has the same air leak sound but I needed to put the van back together for a short break in snowdonia last week.No problems the van pulled like a train,and strangely,no puffs of smoke that I used to get when accelerating,very odd.I just would like to say thanks for the advice and keep up the great work .Many thanks .Russ

Fantastic news!! Glad it worked out. It may be worth you checking the brake servo hard plastic hose line that runs from the servo to the vac pump on the front of the engine, these can wear through especially where they cross the top of the radiator. Small hole draw vac making a noise similar to what you hear. I would have expected if this was the case that the brake efficiency was down a little though (hard pedal).

Keep in touch

Steve

This is brilliant thanks, I’ve just replaced the vacuum solenoid on my ’04 311cdi trying to cure a cutting out problem (accompanied by a loud knocking/rattle and clouds of smoke) codes were P1470 charge pressure negative control – charge pressure low alomg with P0201/2/3/4 high current common wire.

It’s cured the cutting out and now just occasionally goes into limp so next job is to check-out the wiring to the vac’ solenoid.

I found reference to a repair section of wiring on a parts list published on a Russian website (genuine mercedes part) but now can’t find my way back to it, looks like I’ll have to cut & splice?

BTW, something is blocking me saving this site to favourites, nothing happens when I right-click.

Thanks

Max

Hi Max,

Thanks for the good comments. Sounds like you are on top of it now.

The wiring loom at the front is quite simple to splice into as there is only a couple of wires to trace back through, so I would go for that option. The Gen In site pages are deactivated against right click to make it a little less simple to copy photographs/content etc. I am sure the favourites – ‘add to list’ will still work if launched as part of your browser favourites function.

Let me know how you get on with the Sprinter.

All the best.

Steve

Rather than splitting the existing harness (not a lot of room for red crimps & heat shrink), I’m looking into using OEM parts and do a proper job. The parts list is a little difficult to decipher but I think I can order a new plug & terminals for the solenoid end and terminals & plastic holders(?) for the ECU end (looks like the terminals &holders slide out of the multi pin plug at the ECU?). It’s going to be difficult to get the new wires through the bulkhead grommet, what do you reckon?

Max

Hi Max.

I take it you have seen/measured a fault in the wiring continuity between the ECU and Solenoid? What I would consider doing is splicing in to the loom just on the engine side of the bulkhead grommet, where access is easy. If you cut here you can measure and prove all is well back to the ECU from this point, and run your cable to the solenoid easily within the engine bay. The problem area with the existing cable will most likely be where it hooks round the rad/intercooler, so splicing in here should be a good compromise. I would use solder and heat-shrink the joins, maybe even use self-amalgamating tape, like you say crimps are not the boys for this job! If you do need to get into the ECU area in the cab from the engine bay the best way to do this is puncture the grommet towards its middle near the central core of wires with a bradawl or terminal screwdriver, push your wires through a tightly made puncture hole and they will be almost self sealing through the grommet. You are correct in that the ECU plugs have a slide out connector inner within the latch assembly. Hope this helps.

All the best

Steve

The boost control went ape again the other day after a heavy downpour so I think it must be moisture getting into the harness somewhere, once everything had dried out and I’d sprayed the harness & connectors with GT85 she’s fine again.

I’ll give soldering a go, just need an assistant to hold the wires as I never seem to have enough hands [one for the iron – one for the solder etc :)] .

Here we are again, right back at square 1

I rewired the boost control valve weeks ago and things have been fine since then, until another really heavy downpour on Saturday and she’s back to cutting out again, EDC warning light is on constantly and power is down.

I’ve done all the usual checks, cleaned & GT85’d every terminal block I can find to no effect so will have a go tomorrow following your diagnostic guide above. Is there any particular point that is prone to water ingress I should concentrate on? (the ECU is fine, bone dry).

On a slightly different topic, I cleaned & lubricated the brake bias valve linkage & actuator today but can’t figure out how it’s supposed to work, the short spring holds the actuator in the “closed” position, it appears to me that the linkage off the shocker mount tries to pull it even more “closed” , can you advise?

Thanks yet again.

Max

Hi Max,

You seem to have covered most everything. I take it you replaced the loom section by the passenger headlight as it rounds the intercooler? (this is where the loom rubs/fractures commonly) It is possible that it is unconnected to water ingress. A stab in the dark would be either Camshaft or Crank sensor – this may or may not be associated with poor starting. I have had similar issues with low pressure fuel delivery and a filter change has cured this. As always you are better to invest in a read of the fault codes and save all the guess work.

The brake load sensing proportioning valve is in simple terms a sliding piston in a housing bolted to the chassis, this piston varies fluid passage ‘orifices’ dependant on its position – ie. how far the piston is allowed to extend under braking pressure. The arm and spring mechanism bares on the piston head to control the pressure required to force the piston out under braking and thus the amount of brake force applied to the rear wheels (by regulating brake fluid flow through the orifices) with regard to van loading. Allowed to extend outward, the braking force to the rear wheels is reduced to a minimum, fully retained inward the transmitted brake force will be at maximum. Have a read here: http://sprinter-source.com/forum/showthread.php?t=21459

Hope this helps.

Regards Steve

Hi Steve, back again.

She finally failed to start today after another heavy downpour (there’s a theme developing here), Snap-on code reader is comiing up with P1190 fuel pressure control valve open circuit.

A few questions – is this the one under the vac’ pump on the front of the head and would partial failure (before todays complete fail) give me the 3000rpm limp home symptoms? It’s hard to tell the condition of the wiring but it certainly doesn’t look as bad as the boost control solenoid was prior to rewire, is this a known wiring fault?

Thanks once again for all your help, keeping white van man moving, when we’ve both got more time I’d like to discuss tuning chips with you, specifically taking my 311 up to 130ish BHP.

Cheers.

Forget the bit about it being under the vac pump, it’s on the back of the fuel rail isn’t it? Is there any way the valve can be tested or any checks I can do to the wiring ie testing for a voltage at the terminals before the valve is condemned?

Thanks again.

Did a bit of playing today while waiting for the new valve to arrive, I’ve got continuity from the red/white wire at the plug back to the ECU with a pretty low resistance as well and the black/white wire earths to the battery negative just fine. With my meter connected across the valve terminals I’m getting continuity and about 3.5 ohms resistance but that’s with the valve at rest, who knows what it’s like with fuel pressure acting against it?

Max

Hi Max,

There are three pressure devices, one on the LP supply in a Tee on the fuel rail under the inlet manifold towards the front, another on the HP pump, rather like an elongated tower that mounts to the triangular shaped pump with the connector pointing to the inlet manifold side of the engine (Connector is a sod to get on off, but will just make it) finally the HP fuel rail pressure regulator valve, this is the one you are saying is on the fuel rail itself hidden in that small gap under the inlet manifold by the fuel filter canister.

As all things seem to happen when its raining, just make sure there is no water running down the loom from the grommet in the bulkhead where the ECU lives by the bonnet release as it can wet the connectors on the ECU ports.

Keep in touch and let me know progress as these things are rarely straightforward.

All the best

Steve

The ECU was one of the 1st things I checked, all the terminals were bone dry so eliminated that. Got my new pressure control valve fitted it with new seals and… not a peep.

funny thing is, as soon as I switch the ignition on the temperature gauge goes full scale so I suspect a short in the wiring some where, it would be too easy if somehow the red/white supply for the fuel valve had chafed into the temperature sender circuit, off to try and trace it now 🙁

No joy yet, it’s now pitch black and freezing so try again tomorrow, one thought, should the engine start with the top off the inlet manifold or does that mess up some inlet air pressure sensor?

Thanks

Hi Max,

Not the time of year for messing outside is it. Least the nights should start getting lighter now all be it slowly! I reckon it will at least start but don’t expect it to rev freely, it should idle at least of sorts.

Regards and happy Christmas,

Steve

Max, the main problem area for loom faults is where it dips down from the head, under the inlet manifold down past the engine mount. This bunch gives by far the most issues, cut it open and inspect it. The temp sender, fuel filter water sensor, fuel pressure regulator, and fuel pump pressure sensor all run in the same part of the loom at the front of the engine. You can see where they split under the fuel filter and go to their respective positions.

Regards

Steve

Thanks Steve, I’ll give that area some attention between rain showers, I’ll throw another fuel filter on it just in case although the one fitted is only around 5-6000 miles old.

I spent half of yesterday looking for a valve that isn’t fitted on my van, the fuel shut-off under the vac pump isn’t there, no wiring for it from the ECU so that’s one problem I haven’t got? I’ve just worked out (I think) why there are 2 fuel pressure sensors, one on the front of the rail signals the control valve to open/close maintaing correct rail pressure and the one under the manifold signals insufficient pressure and shuts things down?

Max, if you have a non start situation then it could also be either of the following: Camshaft sensor or wiring, crankshaft sensor or wiring, any of the injector connections or wiring. Any failures of the above will prevent the engine starting. Correct on the sensors, under the manifold is low pressure supply sensor/switch.

Regards Steve

One minor success today correcting damage I’d caused (deformed the terminals in the pressure control valve connector block forcing in my meter probes, the male-female terminals weren’t connecting), now when I crank the engine over I get an occasional stutter as though it’s going to start.

The temperature gauge is still flickering around and managed to snap the terminals off the probe when disconnecting (will the engine run without a temp probe connection?) , battery now on charge and my finger tips are blue so try again tomorrow.

A quick question, is there any way of confirming the various probes/sensors are functional without substitution ie by measuring resistance or confirming continuity across terminals otherwise I could potentially spend a fortune buying new components i don’t necessarily need?

Thanks again

Max

Well the good news is she started today, don’t know if it’s anything to do with what I’ve done? The engine is knocking a bit & smoking under load and the throttle response doesn’t seem to bear any relation to what my right foot is doing but she runs (edc light still on all the time) so I can get her to the garage and have the codes read, I know one will be a temperature sensor fault!

Got her to the garage today for a code read, I’ve still got P1190 control valve open circuit but I think that’s being caused by P0190 – Bank 4-6 rail pressure sensor signal voltage too high.

Gonna look for a short between the fuel pressure sensor circuit and the engine temperature circuit that’s possibly what’s causing the fuelling problem and causing my temp gauge to flicker between zero and full scale, fingers crossed it’s not the sensor, that’ll be another £200!

Glad you at least got it to a garage, and it ran of a sorts. It seems there are still some electrical gremlins to sort out. I too have been working over Xmas and its not pleasant outside. I did a timing belt on a Crafter CR35 2.5TDI and a full service – was dresses up like an Eskimo!

Let me know how you get on.

PS. I don’t have any comparison information for metered readings of what is good or bad regarding sensors so cant really help there, sorry.

Well Steve, I’d love to be able to say it was dodgy wiring but no, the fault was with the fuel pressure sensor, new one fitted and she’s running A1, one thing I’m dubious of though is the sealing washer/O ring, the old sensor didn’t have one, it was sealed in with clear fish tank sealant and the new one came with a choice of steel crush washers, I had to use both to get a seal as the sensor bottomed out on the threads before either singularly got a grip, my local VAG dealer will have the correct seal tomorrow.

Next job – remove the thermostat housing to change the temperature probe I snapped, can’t get a grip to pull it out.

One more question – what to do about duff glow plugs, do I just pull a relay/fuse and forget? The garage who do my code reading have given me dire warnings about killing batteries/starter motors.

Thanks again

Max

Result!

Pleased that its sorted Max.

I have never known a thermostat sensor come out yet ! if you manage it you deserve a prize. I always fit a new Febi stat housing complete with sensor and new O ring (All in the kit) for about £35.00 from GT Auto-factors. Its a tight fit to remove once the bolts are removed, made a great deal easier if you remove the oil filter bowl, just cover the open filter with a rag or stretch a rubber glove over it to stop crud falling in. Don’t pinch the wiring loom by the fuel filter when you reassemble.

If you look at the glow control module, under the battery tray area you will be able to identify a thick supply wire going to the unit, right above to the ESPAR auxiliary heater, remove this and tape it up. Forget it, never fitted glow plugs in the UK and the fleet I service has not a single vehicle running with glows without an issue. You invite more trouble than enough trying to remove them and if stuck will cost you a head job if they break off. If you remove the control module plug you will flag a communications fault with the ECU so just remove the battery supply for the glow plug power.

Have fun Steve

Here’s a new one Steve, in my ownership (around 40k miles) the van has always ticked over at 750-800rpm, today it’s gone up to 1000rpm, is this like a petrol engine and I’m looking for an air leak on the inlet side somewhere?

Cheers

Max

Hi Max,

Nope, nothing like a petrol, take the turbo hose off and it will still idle at the norm! More likely to be throttle potentiometer (pedal assembly) or water/coolant temperature sensor fault (engine thinks it needs cold state enrichment and idle-up) The ECU sets idle speed, so it can only be an external control signal that is influencing the change.

MY 2011 ish and a rise in idle could be the DPF doing its ‘cycle’ – if so idle will return to normal once regenerated.

All the best

Steve

That’ll be the broken temperture probe, I haven’t got round to replacing it yet, strange that it’s taken 6 weeks to notice, and it’s back down to normal again today?

Thanks .

Hi Steve

Very interesting information here.